CP&A has been hired by SolAgra Corporation for its structural engineering expertise for two agri-voltaic solar arrays.

Casper, Phillips & Associates Inc. (CP&A) has been hired by SolAgra Corporation for its structural engineering expertise for two agri-voltaic solar arrays that will be built at two University of Delaware campuses in Newark and Georgetown, Delaware to study solar power production on farmland. SolAgra plans to build and launch the solar arrays for the 2024 growing season. The University of Delaware, College of Agriculture will plant test crops beneath the solar arrays and identical control crops on adjacent areas in full sunlight and then compare crop quality and biomass to relate the success of crops grown under the solar arrays to the control crops that are grown in full sunlight.

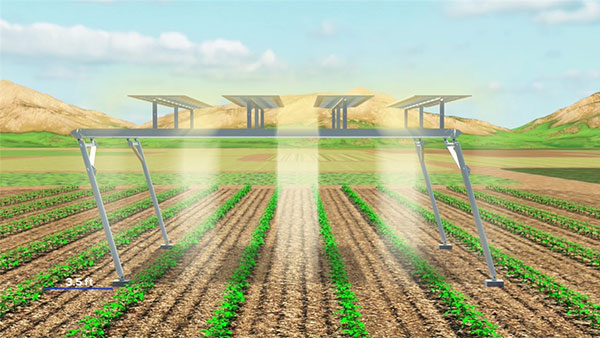

SolAgra Corporation is principally owned by Barry Sgarrella, its CEO/President. SolAgra is a solar firm that specializes in the development, engineering, procurement, and construction (EPC) of Solar Energy projects, focusing on agrivoltaics – the development of dual land use farming using patented elevated photovoltaic solar arrays to produce green energy on farmland while simultaneously sustaining or improving the quality of crops being grown beneath the solar arrays. Agrivoltaics also reduces the irrigation water requirements to successfully grow crops. It also increases the efficiency of the solar panels by microclimate cooling created by growing crops. SolAgra calls its patented technology SolAgra Farming™.

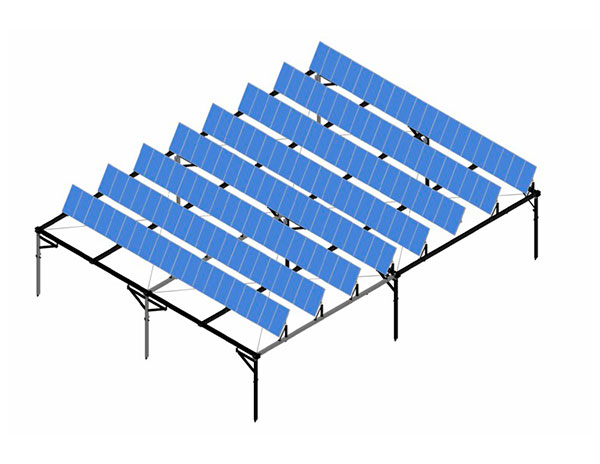

Sgarrella is the holder of U.S. Patents that protect SolAgra Farming – the unique agrivoltaics technology that provides DynamicShifting™ and CounterTracking™ of elevated solar arrays to support the dual use of farmland. These technologies differ from other agrivoltaic solar installations because they are dynamic and variable. Most agrivoltaic systems are static and trade off solar production for plant growth or allow plant growth between the rows of solar but not actually beneath solar arrays. The SolAgra Solar Platform and its hinged design allows multiple configurations for a myriad of crops and can move the structure and control where the sunlight and shade are landing on the field, giving farmers the ability to regulate how much or little shade the crops receive.

Sgarrella said: “… we developed this unique concept to simultaneously expand the viability of solar energy generation and improve food production all over the world by making agrivoltaics financially viable for the farmer and the solar developer. The farmer works cooperatively with SolAgra to provide farmland at a lower cost than SolAgra would typically pay for solar (only) development property. SolAgra pays the farmer for the use of the “air rights” above that farmland by sharing a portion of the power sales revenue in lieu of land-lease payments. The farmer enjoys the shielding from excess sunlight on growing crops and protection from rain and hail that can damage crops and lead to major farm losses. Crops grow with significantly less irrigation water by controlling sunlight/ shade beneath SolAgra Farming arrays. The solar panels produce more power due to the cooling microclimate that occurs when crops grow beneath the solar arrays. This technology can expand the areas of the world where agriculture can occur and helps existing agricultural investments remain productive in areas that would otherwise decline due to climate change. This is a win for the farmer/landowner, a win for SolAgra and a win for the environment.”

The ability to control shade over crops allows for optimizing production of crops in precision agriculture. At the same time, the solar panels can produce power, which will both reduce or eliminate electricity costs for farms and generate a new revenue stream without losing use of any farmland. Because of the variable nature of a SolAgra Farm, it will be applicable in most farming applications, many of which UDel will study in the coming years.

Richard L. Phillips, Mechanical Engineer, CP&A, which specialises in crane engineering, structural engineering, custom software and other specialist services for ports and heavy-duty environments, said it’s interesting to break out from the norm and do something that someone hasn’t really done before, and solve different problems.

“SolAgra has developed this patented design which allows solar panels and crops to share the solar resources on the same unit of land. We do this by using a combination of patented tracking and light passage technologies, created by the SolAgra Solar Platform™, SunSharing™, SunShading™, CounterTracking™ and DynamicShifting™. When combined, using real-time variable computer-controlled tracking algorithms, these technologies allow crops to get all sun that they need, while the solar panels above generate electricity. The solar panels will be mounted on arrays that are 10-16 feet above the ground to allow for large modern farm equipment to pass beneath,” said Phillips.

“CP&A is sizing the beams, developing the loads for the geographic location and overseeing the installation with plans for more projects in the future. We’ve created a template where we can enter geological data quickly then automatically generate more environmental loads.” CP&A is using this template to do the analysis and design for two larger SolAgra Farming projects in California that will prove SolAgra Farming can be used for growing wine grapes and Rainier cherries.

Sgarrella has a long-standing history with CP&A as he previously worked with founders Bill Casper and Rich Phillips before they retired. Bill Casper’s citation of excellence from ENR was awarded because of a collaboration with Sgarrella.

“Barry came to us because he had worked with our founders and needed help with the solar array designs as they don’t fit the standard code of structural analysis. He came up with the idea, got it patented and now we’re helping him do the engineering work,” said Phillips.

Contact for editorial enquiries: Richard Phillips, richard@casperphillips.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.