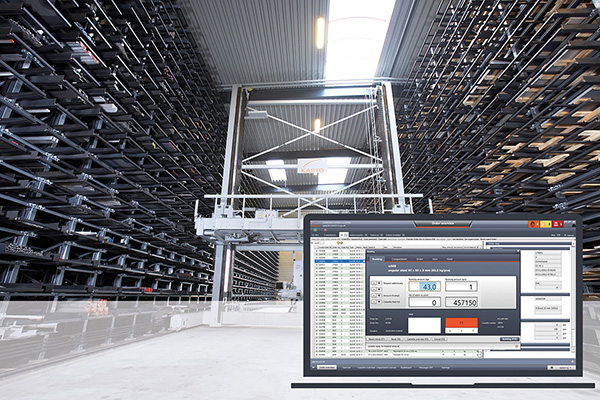

Smart solutions by KASTO automate all processes in the bar stock storage system – from storing the raw material to picking the cut sections.

Metal processors are well aware of the issue: efficiency and speed are crucial when it comes to handling bar stock, tubes, profiles, and metal sheets. KASTO solutions automate all processes – from storing raw material to picking cut sections. Thanks to the digital features, the user always has a clear overview all processes. As a result, the efficiency of both storage and sawing are significantly increased.

Companies in the metalworking industries, such as machine and window construction, sheet metal processing and steel distribution, store and process large volumes of metals. The range of application is vast, and the warehouse goods can vary greatly. Not only do these companies handle bar stock such as bars, tubing and profiles, they also process sheet metal. The rule always applies: storage space is a valuable resource and should be used efficiently. The same efficiency is required when processing and compiling individual orders. The industry uses high-powered, fully automated saws to perform straight or mitre cuts. Some companies still depend on sorting solutions for palletising and picking, which are either cumbersome or rough on materials. Robot handling systems from KASTO can gently remove cut sections directly from the sawing machine. KASTO provides various other solutions that enable end-to-end optimisation of the entire process chain. Users can optimise their process for sawing and storing bar stock and sheet metal in seven simple steps.

To maintain efficient operations in the warehouse, a high-performance system is essential. KASTOlogic manages all processes. The software optimises movement sequences, assists the operator with a graphical interface, and visualises the system. An ERP system and WMS exchange data automatically through standard interfaces. As a result, efficiency and performance increase throughout the entire system while operational and categorisation errors are virtually eliminated. Users can access different modules to customise the software to meet their specific requirements. These requirements include, for instance, the control of automated storage systems, integration of machines and generation of comprehensive statistics for system analytics.

Standardised storage systems are suitable for many applications and materials. However, greater efficiency, space-saving, faster placement of goods, and versatility are sometimes needed. KASTO’s “modular systems” allow precise customisation to individual material flow. Storage and retrieval stations can be tailored to user needs, for instance, by using automated bar separation. The customised design with selectable storage lengths and heights makes it possible to accommodate all formats used, maximising space efficiency. KASTOrail is an intelligent material distribution system that transports picking bundles efficiently and ergonomically for shipping. At the same time, individual materials can be transported between the different processing steps. The system operates with a combination of manipulator and material buffer chain conveyors. The installation on raised rails ensures maximum space utilisation.

KASTO bandsaws and circular saws cut bar materials, sheet metals and profiles with straight or mitre cuts. In addition to high cutting efficiency, users require low idle periods. In response to these demands, parameters such as material qualities and the sawband tailored to them can be stored permanently on the KASTO saws. The control system automatically selects the cutting technology appropriate to the specific job. Not only does this reduce tool costs, it also significantly reduces cutting times. CNC-controlled, fully automated production circular saws like KASTOvariospeed can cut any bar stock to size, regardless of material quality. Where required, the sawing solution can also work in conjunction with the KASTOsort robot handling system.

In the KASTOcenter, automated computer-controlled operating gantry cranes transport individual bar stock to an integrated CNC saw and automatically returns remnants to storage. The software updates the inventories and can trigger new orders if needed. The flexible system consists of a storage system, saw, and control system. KASTO coordinates the components seamlessly, enabling the sawing center to output as much as three to seven individual saws.

After sawing, but before shipping. The sawing specialist created the KASTOsort robot handling system specifically for the automation of palletising and order picking. The system is ready for operation directly behind the saw: it can transfer workpieces to downstream processes such as deburring, length measurement, marking or directly to packaging. The robot automatically calculates the stacking pattern with the highest packaging density. It gathers the required information directly from the ERP system. The decentralised, self-organised program logic makes teach-in or programming by the user obsolete.

The KASTOapp provides users a complete status overview of all KASTO sawing machines in the network. All important parameters, such as article, cut length, target and actual number units, and cutting speed are accessible at any time. KASTOlogic mobile assists personnel in the storage system. By scanning QR and barcodes, for example, you can easily trigger a repeat order when removing items from the magazine. The apps notify users in the event of an operational error, enabling a rapid response.

Thanks to augmented reality, KASTO VisualAssistance offers an option to easily service machines and systems remotely. Service technicians assist users with operation and fault diagnostics using a direct remote connection. The core component is an interactive app for tablets, smartphones or smart glasses.

Automated material handling plays a crucial role in enabling metal processors and distributors to maintain their competitiveness in the long run. KASTO, the storage and sawing specialist, provides smart concepts for an end-to-end process chain. With this system, the individual components communicate with each other independently. This feature ensures high-performance, resource- and cost-efficient processes and maximises productivity and flexibility.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.