Industry is facing once-in-a-generation challenges. Here are three ways that boards can tilt the odds for their companies.

By Tacy Foster and David Pralong

Supply chains are being reconfigured. Wages are rising. Consumer demand is softening. Cost pressures are continuing. The times are not easy for US manufacturers, and making incremental improvements will not be enough to ensure long-term success. Manufacturers will need to re-think how they do everything. Like it or not, they are entering a period that demands transformation, meaning an intense, organization-wide program that shifts performance, starting with the top line.

Navigating such change is at the top of the agenda for leadership teams. But it cannot be left solely to management. Rather, as the guardians of the company’s future, boards have to ensure that performance efforts leave the company better off, and not just more presentable at the next quarterly earnings call.

Three principles can be helpful in guiding these transformation efforts.

Insist on change management that puts organizational health front and center. Change is intimidating at the best of times. Today, manufacturing is at the confluence of several threads of change, including labor constraints, automation and economic uncertainty.

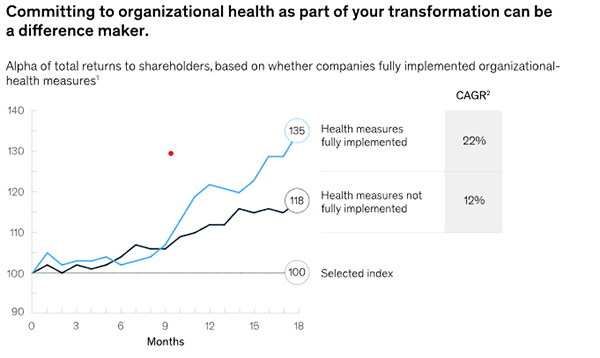

Research shows that a strong culture accelerates and strengthens transformation efforts. The total return to shareholders after a transformation is 10 percentage points higher for companies that invest in culture and capabilities (see exhibit).

A positive culture can also build trust. That matters, because lack of trust can bury a transformation before it gets going. Make sure frontline workers are involved from the start. Substantial employee involvement is associated with higher returns; building such engagement, though, requires a change in mindset. For example, transformational change cannot happen if people are afraid to fail. McKinsey research has found that organizations that undertook successful digital transformations were more than twice as likely as their peers to strongly agree that employees are rewarded for taking appropriate risks. There is also a robust correlation between quality and culture. Organizations that make quality an imperative for everyone—a matter of culture—are much more likely to see substantial performance improvements.

Make skills development a core part of the transformation. Given rising labor costs and accelerating automation, US manufacturing is facing a once-in-a-generation discontinuity. Boards ought to have a quantified view of where the company needs to be in terms of production footprint, labor intensity and capabilities. Without such view, it is all too easy for management to manage quarter-by-quarter and miss the shift in what will determine competitiveness in the next few years. No transformation can go faster than existing capabilities; a supervisor who now oversees a manufacturing line will also need to develop new technical skills, such as automation and artificial intelligence (AI).

Not only will employees need to train to use new technology, but the Board will also need to decide what obligations the company has to existing employees and those who could be displaced. Every business relies on a social license to operate, and this is particularly true around manufacturing sites. In the most recent Edelman Trust Barometer, business was the only institution seen as both competent and ethical. It is up to the board to define how to meet these responsibilities.

Communicate with capital markets and shareholders. Because of the need to invest in new technology and training, manufacturing transformation will not come cheap. Existing approaches to capital investment may have to be reconsidered, such as how it is accounted for on the balance sheet. Given the need for significant and swift investment in automation and AI, the likely result is to reduce both free cash flow and returns to shareholders. It is up to the board to explain the business case for going as fast as possible, and why the long-term gain will make the short-term hit worthwhile. Management needs to ensure that this happens; but it is up to the board to set the tone.

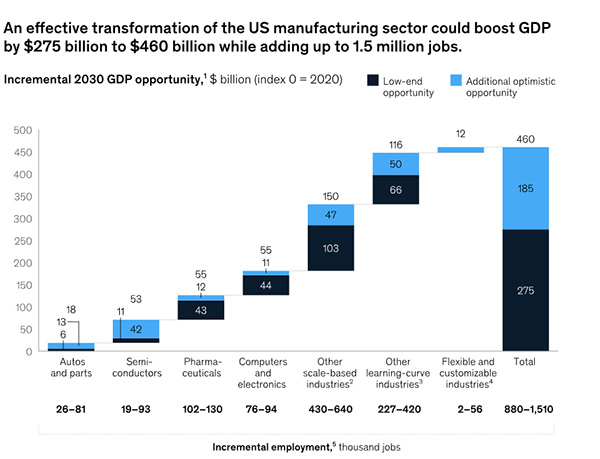

There is no way around it: US manufacturing is facing a period of discontinuity. Like all such periods, the opportunities are substantial—on the order of more than $400 billion in additional GDP (see chart).

Coping well places demands above and beyond what frontline staff can be expected to manage. The only way to thrive, or perhaps even survive, is to find interventions that go beyond routine tweaks to individual business units and instead transforms the whole organization.

In important ways, the future is now: it is up to boards to actively shape it.

Tacy Foster is a partner in McKinsey & Company’s Charlotte office. David Pralong is a senior partner in Charlotte and managing partner of the Carolinas office.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.