Manufacturers must refine strategic scenario planning and proactive approaches, says the Grant Thornton Head of Manufacturing.

By Kelly Schindler, Head of Manufacturing at Grant Thornton Advisors LLC and an Audit & Assurance partner at Grant Thornton LLP

Strategic planning has now become even more essential for manufacturers. Our industry faces a whirlwind of new federal laws, regulations, and enforcement measures — some on the horizon and some already here. This rush of change demands a bold and proactive approach to strategic planning.

Manufacturers need to reflect on who they are now, who they want to be in the next five to 10 years, and how they plan to get there. Strategic planning is not just a guiding principle; it’s a necessity for navigating the complexities of the current and future market.

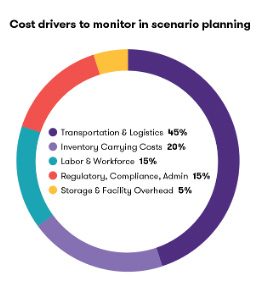

I’ve heard many of our manufacturing clients express concerns about tariffs. During the recent election, we heard President Trump talk about significant tariffs for China and on imports across the board and we’re starting to see these take effect — although it changes by the hour — and retaliatory tariffs are also being imposed. Such tariffs will mean a cost increase for manufacturing companies — for many, that cost could be quite substantial. Beyond tariffs, we must also consider potential changes in health regulations, critical minerals, energy availability, labor, immigration, and taxes.

Taxes have been a big concern for manufacturers, and throughout 2024, the National Association of Manufacturers sought an extension of important provisions from the Tax Cuts and Jobs Act. The potential for new tax rates and regulations in 2025 can significantly impact business strategies and investment decisions for all industries, but especially manufacturing.

To confront the multitude of challenges and unknowns, scenario planning is essential — and it must involve understanding both the potential changes and their impacts. For manufacturers, this means considering the potential failures or difficult scenarios they could face and identifying the most appropriate way to respond. When evaluating their options, they must also recognize that none may be ideal, but it’s best to know and prepare in advance. By doing this, you can become more prepared to act with insight, preparation, and speed.

For example, analyzing revenue to re-prioritize and adapt strategies if new policy changes could negatively impact revenue. This includes knowing exactly where revenue comes from, understanding customer segments, understanding what your plants are capable of (think outside the box), and identifying critical and strategic customers.

This also includes looking back and analyzing supply chains to understand where products are made, what goes into them, and what options are available for alternative sources of supply.

Once you have identified risks and planned for different scenarios, it is crucial to take proactive steps that build resilience. When you think about the actions that you would potentially take, you can see the conversations that leaders need to be having today. This includes building relationships with alternative suppliers, engaging in potential strategic partnerships, initiating discussions about potential workforce changes, and considering technology modernization and automation.

For instance, leaders should begin by reviewing current suppliers and considering alternatives. Vetting suppliers and having open conversations about future strategy will help lay the groundwork that can improve your position if you need to act on your alternative scenario plans. Also consider the impacts of technology initiatives on your workforce. It’s a good idea to plan for workforce upskilling and create promotion paths alongside any new technology adoption.

On the technology front, it is also important to watch and anticipate emerging trends and technologies that could impact the industry. For example, the development of domestic semiconductor supply chains, as supported by the CHIPS Act, presents both opportunities and challenges for manufacturers. Similarly, the focus on critical minerals and the need to foster alternative supplier relationships highlight the importance of staying agile and adaptable. Potential changes in health regulations, such as the Make America Healthy Again initiative, could have significant implications for food and beverage manufacturers.

By staying informed and proactive, you can ensure that you are well prepared to navigate these changes and continue to thrive in an ever-evolving landscape.

Strategic planning is not just about preparing for the future but actively shaping it. Manufacturers must understand where they have exposure today, think about their options, evaluate those options, then put plans in place now because we all know it can take considerable time to rollout.

By understanding potential changes, engaging in scenario planning, and taking proactive steps, you can navigate the complexities of the current and future market with confidence and resilience. Now is the time for manufacturers to reflect on how they plan to achieve their visions. The challenges are significant, but with a robust strategic plan and a proactive approach, manufacturers can turn these challenges into opportunities for growth and success.

About the Author:

Kelly Schindler is the national managing principal of Manufacturing at Grant Thornton Advisors LLC and an Audit & Assurance partner at Grant Thornton LLP. In her leadership role, she oversees the growth and operations of the firm’s Manufacturing industry, which encompass a full range of audit, assurance, tax and advisory services. She also regularly visits domestic and international offices to meet with manufacturing clients and prospects, providing industry insights, identifying solutions to client challenges, and fostering connections between manufacturing companies to share best practices and network.

Schindler has been with Grant Thornton since 2011 and has more than 20 years of experience in public accounting. Before joining Grant Thornton, she was a senior manager at another large professional services firm, where she managed several domestic and international public and private company engagements. She also worked overseas during the rollout of the International Financial Reporting Standards (IFRS) and led global trainings on how to implement effective inventory cycle counts at large, international companies.

Schindler plays a key role in educating the firm’s professionals on the latest industry developments, including tax regulations, international business practices, workforce dynamics and supply chain management. She is also a board member of the National Association of Manufacturers, where she works to bolster the association’s leadership in policy advocacy, legal action, workforce solutions and operational excellence.

Schindler is a CPA in Missouri and Iowa and a member of the AICPA. She is also a member of Women in Manufacturing, both locally and nationally, and serves on Missouri State University’s Advisory Board.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.