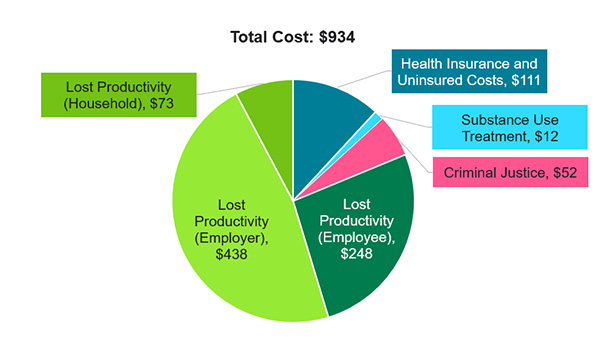

American manufacturers are losing $438 billion annually to a preventable crisis, according to a new report by Avalere Health.

By Claire Bryant, MPH, CHES

Opioid use disorder is costing companies skilled workers just as the manufacturing industry faces 1.9 million unfilled jobs by 2033.

Two out of three manufacturers say recruiting and retaining talent is their biggest business challenge. The opioid crisis makes this worse.

Manufacturing, construction, and extraction workers face higher injury risks. Workplace injuries can lead to chronic pain and, without proper care, opioid dependence. The result: companies lose skilled workers when they need them most.

The numbers are staggering: untreated opioid use disorder costs nearly $700,000 per worker annually—over $1 million in manufacturing states like Ohio. But employers who retain workers in recovery save $8,500 per employee while keeping skilled talent.

Here’s the disconnect: National Safety Council (NSC) research shows 85% of employers know about opioid overdose reversal medications (OORMs), but fewer than half actually have opioid overdose response kits in their workplaces. This gap represents an immediate opportunity to save lives.

NSC provides resources for businesses to become Recovery Supportive Workplaces. According to the Department of Labor, these workplaces benefit both employers and employees by increasing worker wellbeing, improving productivity and reducing overall health costs.

Integrating FDA-approved OORMs into first aid and emergency preparedness programs is an essential step for organizations to take. Through its Respond Ready Workplace program, NSC is committed to working with employers, government agencies and other stakeholders to:

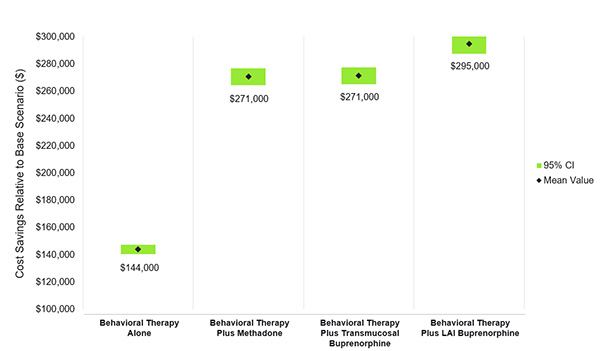

Workplace programs are just the beginning. As with most other chronic conditions, opioid use disorder is treatable. Effective treatment saves lives and money. For example, when paired with behavioral therapy, long-acting injectable buprenorphine can reduce the cost-per-case of opioid use disorder by $295,000.

Employers can strengthen their workforce by covering all evidence-based medications for opioid use disorder plus behavioral health support, giving employees and doctors flexibility to choose effective treatment. While not all paths to recovery involve medication, these treatments increase the likelihood of recovery and help keep workers healthy and employed.

Reducing treatment barriers strengthens our manufacturing workforce. System and policy changes must expand access to proven treatments.

Manufacturing safety professionals can start by:

Addressing opioid use disorder must be part of any serious strategy to keep America’s manufacturing workers safe. Without a healthy workforce, even the most advanced and well-funded facilities won’t run effectively or efficiently.

The choice is clear: we can continue losing skilled workers to a preventable crisis, or we can take action. Let’s take steps to meet the moment and give hardworking Americans the tools they need to succeed.

About the Author:

Claire Bryant, MPH, CHES is a public health professional working on the Council‘s workplace wellbeing initiatives. Claire is responsible for planning, implementing and evaluating initiatives, such as addressing workplace substance misuse and fatigue. This entails researching relevant topics and providing analysis for technical reports and initiatives to strategize and build future programs.

As a Certified Health Education Specialist, Claire also focuses on creating tools to aid employers in addressing substance misuse and other forms of wellbeing safety risk in the workplace. She works to create and draw awareness to holistic interventions that address impairment from any cause in the workplace, such as workplace training and impairment detection technology. Claire holds a Master of Public Health with a concentration in policy and management from the University of Georgia, where she also completed her undergraduate degree in health promotion and behavior. A native Georgian, she now resides in Chicago.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.