Award-winning solution is in response to aerospace industry demand for an automated tool for precision masking tape application.

HUNTSVILLE, Ala. – Aerobotix and FerRobotics, two leading robotics companies based in the U.S. and Austria respectively, today officially announced they have partnered on a new solution in response to aerospace industry demand for an automated tool for precision masking tape application.

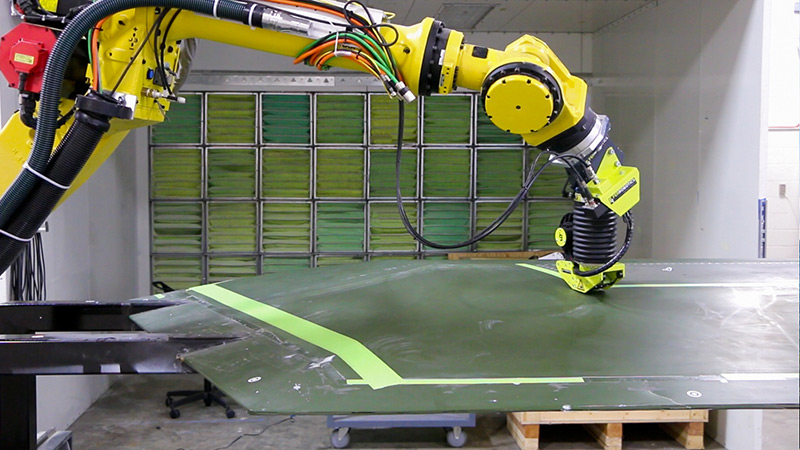

Collaboration between engineers from the two companies has led to the development of a revolutionary End of Arm Tooling (EOAT). After months of prototypes and testing during the pandemic, the new Active Taping Kit (ATK) tool was completed, with FerRobotics’ patented Active Compliant Technology (ACT) enabling a robot to use varying pressure when applying tape to an aircraft. The tool allows for smooth masking on parts varying in shape and puts down perfectly straight tape lines where the customer needs them.

“Customers have been asking Aerobotix to automate the masking process for years,” said Chris Kolb, Aerobotix Vice President of Sales. “The response was always ‘wouldn’t that be great,’ but the technology required to do it correctly just wasn’t available yet. The FerRobotics ACT device lets the robot ‘feel’ the part and instantly adjust the pressure used to apply the tape. We needed this sensitivity to put masking tape down correctly and not damage high value parts.”

A leading example of Industry 4.0, the FerRobotics ATK features unmatched technology, with precision control of all individual process parameters – contact force, cutting, and tape consumption. The ready-to-use solution offers robot-compatible sensitive tape application combined with all the benefits of the ACT system cooperation.

“The ATK offers the highest process quality from one source, and with a design that’s compact and light,” said Dr. Ronald Naderer, FerRobotics Founder and CEO. “It’s extremely durable and is designed to apply various kinds of tapes on any part or surface with exact repeatability and without bubbles or wrinkles. This joint project with Aerobotix has resulted in an innovative product that should thoroughly satisfy customer needs.”

The ATK exceeded expectations for precision and reliability when it underwent testing at Aerobotix’s in-house process laboratory – a facility housing a range of automated systems used to paint, cure, sand and inspect products for aerospace and defense customers. The ATK’s automated masking process is predicted to revolutionize the painting process and is already being tested on several aircraft.

Funding for this international project was provided by the Air Force Research Laboratory (AFRL), led by Dr. Carl Lombard, materials research engineer. The scientific research organization recognized the potential value in the EOAT concept and assessed that manufacturing downtime during the pandemic offered a good opportunity to support development and testing. Additionally, Dr. Lombard’s exposure to programs where manual masking is impacting costs and delivery schedules made him, and the AFRL, the right fit for financially backing the development of this new solution.

“We jokingly call it our pandemic baby,” said Kent Pfeifer, Aerobotix Process Engineering Manager who led the project’s U.S. team. “Both of our companies had some extra bandwidth during the pandemic disruptions, and because AFRL had some funding to back us, we just went for it. We are running all types of masking tapes through the ATK and, so far, they’re all working great. What we didn’t realize going into this is that having the robot put down the first tape lines saves the painters a ton of time and errors, as they then don’t have to measure or use templates to get the tape lines accurate. The savings, in time and costs, are exceeding all our expectations.”

In November, the ATK was honored as one of only five projects to be nominated for the Econovius, a special prize under the Austrian National Innovation Award. The successful nominees were selected from more than 400 entries. The Austrian Federal Ministry of Science, Research and Economy presents the ANI Award annually to encourage companies to develop innovative products that contribute to the country’s economic growth.

To watch a video about the Active Taping Kit (ATK) tool, click here: https://youtu.be/yyPiFrJF-W8

About Aerobotix

Headquartered in Huntsville, Alabama, Aerobotix is an innovative leader in robotic solutions for the aerospace and defense industries. The company specializes in the creation of cutting-edge automated robotic solutions for high-value, high-precision components, aircraft and vehicles. Aerobotix has more than 130 robotic systems installed in the U.S. and abroad, providing exceptional results and savings for our clients.

About FerRobotics

FerRobotics is the global leader in the development and distribution of sensitive robotic elements (for robotic material removal end-of-arm tooling/surfacing finishing end-of-arm tools/end-effectors) that equip an industrial robot or cobot with contact intelligence and real force control. We give robots feeling with our patented Active Compliant Technology. And this ensures more efficient, finer, and more valuable production results. Our products close automation gaps seamlessly and are trendsetters in flexible automation in numerous industries on the international market. Our experts will happily show you solutions for your applications (robotic grinding, sanding, polishing, brushing, deburring, taping, etc.) or other requirements.

Contact

Dave Foster

Dalton Agency

615-515-4899

dfoster@daltonagency.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.