Adopt agile, data-driven planning to navigate manufacturing variability.

By Laure de Saint Germain, Global Marketing Director, Finance Solutions – Board International

In the face of a constantly changing operating environment, business leaders need to pivot and adapt quickly to ensure they maintain profitability, improve productivity and drive innovative new products and services. Even the most thriving companies are not exempt from navigating constant variability, and this is compounded this year by the looming 2024 election season that will inevitably impact operations across the manufacturing sector.

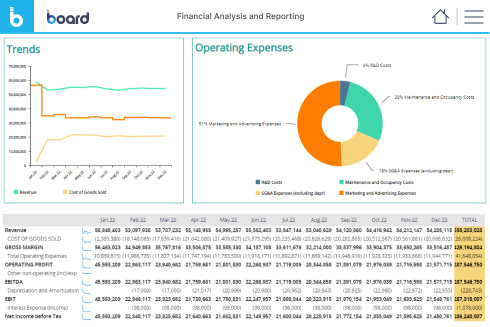

As such, it is crucial now more than ever for manufacturing leaders to consider new approaches to improving everyday operations and adopting new technologies to stay ahead of changing markets. For leaders in manufacturing, navigating variability means adopting an agile, data-driven approach to planning that enables them to improve decision-making based on real-time insights for the short and long-term.

According to a study of 1500 industry-wide decision makers in Board International’s 2024 Global Planning Survey, while 70% of manufacturers globally believe their organization is equipped for agile planning, only 16% have the right processes and technologies in place to make this a reality. In an ever-changing business landscape that has pushed companies into a state of continuous planning, being equipped with the right technology – based on real data insights – is crucial to driving effective planning and decision-making and closing this agile planning gap.

Before implementing new approaches to planning and decision-making, manufacturers must recognize the systems currently in place that might be slowing growth and profitability. According to the survey, 47% of manufacturers use spreadsheets like Excel for at least half of their business planning, hindering collaboration, data management and real-time insights. These legacy systems, which rely on manual data entry, increase the likelihood of human errors and lead to a lack of real-time data integration. As a result of these legacy systems, the survey also found that 66% of companies fail to consider enough potential future scenarios when planning, which can also leave them unprepared for unexpected events.

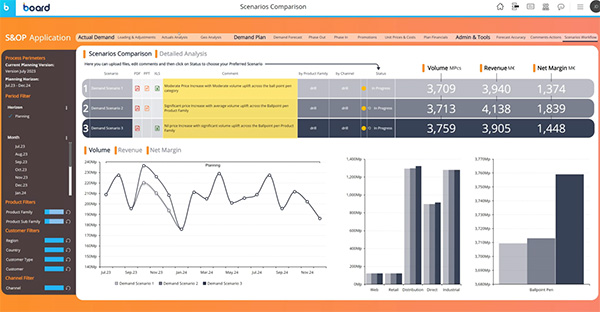

Agile planning solutions can help manufacturers increase flexibility, streamline operations, ensure faster time-to-market, improve collaboration and bolster resource allocation. By working collaboratively from a single platform across operations, manufacturers can drive improved data-driven decision-making at faster rates in near real-time, mitigating the risk of decisions based on inaccurate or outdated data.

In addition to the challenges presented by an overreliance on static spreadsheets, according to the Global Planning Survey, manufacturers’ ability to drive agile, enterprise-wide planning is also held back by poor data quality and governance (48%), ineffective processes based on largely manual activities (48%) and a lack of modern tools and technologies (46%). However, as an encouraging sign, many manufacturers recognize the limitations of their current systems and approaches and have begun embracing game-changing innovations including AI.

The survey found that nearly half of manufacturing leaders (45%) are exploring machine learning and a slightly higher percentage (46%) are considering AI-powered business intelligence tools to enhance their decision-making processes in response to key business challenges. Further, a third (36%) of respondents also plan to adopt generative AI tools to enhance their decision-making process. With a strong data foundation to fuel AI-enabled decision-making, manufacturers will be able to drive improved planning based on the latest insights, to set themselves up for continued success in both the short and long term.

While taking the next step in the adoption of a data-driven agile planning framework is essential to both navigating variability and maintaining profitability in the years to come, manufacturers must also ensure that they are building a culture of continuous improvement. This requires active involvement by leadership teams, who, by building a foundation for ongoing improvement, can drive effective planning and decision-making even amid an uncertain operating environment. By taking this approach to adopting a single platform based on real-time data and insights, teams across different departments are better equipped to manage critical decision-making. This combined approach will drive more effective planning amid evolving business needs and an ever-changing market while allowing manufacturers’ finance and operations teams to work towards a shared vision of success.

Laure de Saint Germain is a seasoned professional with over a decade of experience with technology supporting the office of finance. From cloud to AI, Laure has supported the emergence and growth of major software companies globally, designing go-to-market strategies centered on customer value and future-proof solutions. Witnessing the rapid evolution of technology, she supported many transformation projects, streamlining processes and enhancing collaboration. Laure is committed to leveraging her extensive experience and expertise to propel businesses towards success in an ever-evolving digital landscape.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.