Manufacturing’s 2.4M unfilled jobs aren’t a skills crisis – they’re a capability gap. Here’s how to build the workforce Industry 5.0 needs.

By Trond Undheim, CEO of Yegii, Inc., author of The Platinum Workforce and co-author of Augmented Lean

In November 2022, Natan Linder and I wrote in these pages about the coming Industry 5.0—the era of augmentation where humans and machines would work together, honing each other’s skills in unison. We argued that this paradigm, which we explored in depth in Augmented Lean: A Human-Centric Framework for Managing Frontline Operations (Wiley, 2022), represented manufacturing’s future: not the 24/7 fully automated factory with no humans involved, but rather augmented operations where technology amplifies human capability rather than replacing it.

Three years later, that vision is manifesting faster than we anticipated. Augmented reality applications, digital work instructions, real-time performance tracking, collaborative robots, and AI-assisted decision-making systems are proliferating across factory floors. Yet as these technologies deploy, we’re discovering a critical gap: traditional workforce development isn’t preparing workers for augmented environments. We’re training for skills in isolation rather than building the adaptive capabilities that human-machine collaboration actually demands. The EU’s notion of Industry 5.0 merges sustainability, human-centricity, and resilience, which is a tall order.

Deloitte projects 2.4 million unfilled manufacturing jobs over the next decade, potentially affecting $2.5 trillion in economic output. The industry’s response has been substantial—billions invested in retraining programs focused on technical certifications and tool proficiency. This foundation has been essential and has taken us far.

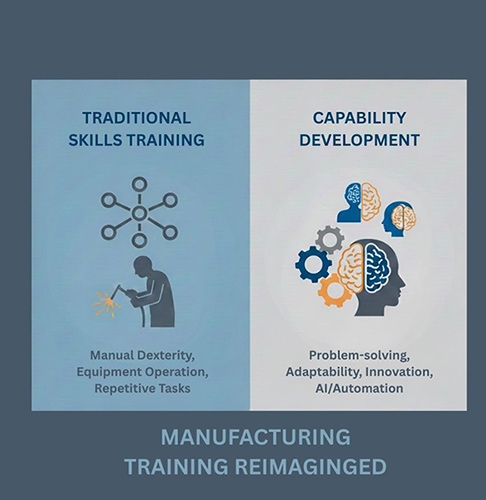

Now we’re ready for the next level: building the capability-based workforce that Industry 5.0’s augmented operations require. The skills vs. capabilities distinction matters because augmented manufacturing creates fundamentally different demands.

Skills are task-specific competencies: operating equipment, reading quality charts, programming cobots, using digital work instruction systems. They’re what traditional training programs excel at developing.

Capabilities, by contrast, are adaptive attributes that allow workers to thrive in augmented environments—where AI provides recommendations that may conflict with experience, where real-time data streams require constant interpretation, where cross-functional coordination happens through digital systems that weren’t designed for human workflow patterns (see Fig. 1).

In my work on digital manufacturing training and real-time work instructions systems, I’ve observed this gap repeatedly. Workers receive excellent training on how to use augmented reality interfaces or follow digital work instructions, but struggle when the system provides ambiguous guidance, when sensor data conflicts with their shop floor knowledge, or when they must coordinate across functions using tools that assume stable processes rather than continuous adaptation. On several lines I’ve observed firsthand—especially in high-mix, low-volume environments—frontline workers rely on judgment, not just instructions, to keep augmented operations flowing.

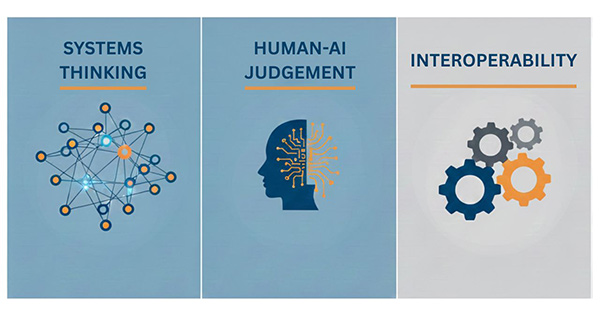

After observing hundreds of frontline workers interact with augmented systems, I’ve identified three capabilities in my new book The Platinum Workforce that consistently distinguish those who excel in human-machine collaboration. These capabilities build directly on the augmented lean principles we outlined in 2022 (See Fig. 2).

1. Systems Intuition

The ability to see how changes in one part of an augmented operation cascade through the entire production ecosystem. When a predictive maintenance algorithm recommends preemptive part replacement, the systems-intuitive technician doesn’t just follow the digital work instruction—they anticipate impacts on production scheduling, inventory management, quality metrics, and safety protocols.

In augmented lean environments, this capability becomes essential because digital systems provide local optimization recommendations that may create global inefficiencies. Real-time data and analysis, as we noted in 2022, is “the new gold” and allows for less hierarchical control—but only if workers can reason systemically about what the data means and how their decisions affect downstream operations.

2. Human-AI Judgment

The capacity to know when to trust algorithmic recommendations and when human experience should override them. This is the cornerstone capability for the man-machine systems we described in Industry 5.0. As manufacturing delegates more decisions to AI—from predictive maintenance to quality inspection to production optimization—the critical human skill expands from execution to include judgment about algorithmic reliability.

Through my work with real-time work instructions and digital manufacturing training systems, I’ve seen this play out repeatedly. Workers who develop strong human-AI judgment can explain when they trust the system’s recommendation and when they don’t, and critically, they can articulate why. They understand that augmented systems complement human capability but don’t replace human judgment—exactly the dynamic we envisioned in our 2022 discussion of cobots and other forms of man-machine collaboration.

3. Interoperability Mindset

The ability to operate effectively across organizational boundaries using augmented systems that weren’t necessarily designed for cross-functional work. In Industry 5.0 environments, workers coordinate through digital platforms, real-time dashboards, and augmented reality interfaces. Success requires more than understanding your own function—it requires the capability to translate your needs into terms other functions understand, interpret their data streams, and coordinate effectively despite using different augmented tools.

This capability directly supports the augmented lean principle of giving frontline workers “higher ability to make good decisions” through data-driven decision-making. But that ability only materializes when workers can interoperate across the complex digital and physical boundaries that augmented manufacturing creates.

Consider how these capabilities manifest in real-world augmented manufacturing environments.

Digital Work Instructions + Human Judgment: Across automotive manufacturing, companies are implementing digital work instructions with AI-powered recommendations. As reported in ASSEMBLY Magazine, AI is increasingly used to predict optimal process parameters, while workers must develop judgment about when algorithmic recommendations need human override based on shop floor conditions. A 2020 IEEE paper on AR-based work instructions in manufacturing found that augmented-reality tools generally reduce assembly errors compared with paper instructions, though there is often a trade-off between speed and accuracy. Traditional training teaches workers how to follow the instructions—tap here, scan there, confirm completion. Capability-based training goes further, placing workers in scenarios where the digital instructions conflict with their assembly experience, where the AI-recommended sequence seems inefficient for specific part variations, where real-time feedback suggests process adjustments that might affect downstream quality.

Predictive Maintenance + Systems Thinking: A Midwestern manufacturer using predictive maintenance systems saw 30% reduction in unplanned downtime after redesigning training to develop human-AI judgment. Their technicians learned to trust the system’s pattern recognition for routine wear patterns while applying human judgment when shop floor conditions—ambient temperature variations, usage intensity changes, material quality fluctuations—meant the algorithm’s recommendation needed contextual adjustment.

Augmented Assembly + Capability Training: A biopharma company replaced 80-page paper SOPs for complex equipment line changeovers with digital work instructions. This fully digital, human-centric approach enforced data collection and streamlined sign-offs for Quality and Maintenance, reducing the end-to-end changeover time from 14 days to just 3 days (a 78% reduction). The core capability gained was cross-functional compliance confidence through real-time audit trails and mandatory digital approvals, not just mere speed.

Enhancing workforce development for augmented operations doesn’t require abandoning existing programs. Start with tactical pilots that demonstrate value quickly.

Week 1-4: Audit Augmented System Utilization

Week 5-8: Pilot Ambiguous Augmented Scenarios

Week 9-12: Launch Cross-Functional Digital Collaboration

Months 4-6: Redesign One Augmented System Training Program

Ongoing: Integrate With Performance Systems

In a previous article for Industry Today, What Industries of the Future Might Look Like, we noted that achieving meaningful augmentation would require “20-50 years, perhaps more, of humans and machines working together and honing each other’s skills in unison.” We also emphasized that “if a pervasive focus on augmented lean does not happen across industry, we would not get to this next paradigm shift even in the next century.”

Capability-based workforce development is how we make that focus pervasive. It’s the practical implementation of the augmented lean principles we outlined: enabling workers to do their jobs better, with more autonomy, while retaining meaning, control, and pride. When workers develop systems intuition, human-AI judgment, and interoperability mindset, they don’t just operate augmented systems—they improve them, innovate with them, and realize the full potential of human-machine collaboration.

The 2.4 million projected unfilled jobs aren’t inevitable. They represent an opportunity to build workforce development that matches what augmented manufacturing actually demands. Traditional training delivered the workforce that built modern U.S. manufacturing. Capability-based development will build the workforce that leads Industry 5.0.

Manufacturing has always thrived when its people do. The era of augmentation we described in 2022 is here. Now we must build the workforce capabilities that allow human and machine to truly hone each other’s skills in unison. That’s how we realize not just the technology of Industry 5.0, but its promise: manufacturing where human capability is amplified rather than diminished, where workers innovate rather than simply operate, and where the future we build is one we actually want to see.

About the Author:

Trond Arne Undheim is former Research Scholar at Stanford’s Center for International Security and Cooperation, former Inaugural Director of MIT Startup Exchange, and author of Augmented Lean: A Human-Centric Framework for Managing Frontline Operations (Wiley, 2022) and The Platinum Workforce: How to Train and Hire for the 21st Century’s Industrial Transitions (Anthem Press, November 25, 2025).

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.