Dynamic Load Monitoring (UK) Ltd. (DLM), of Southampton, UK has received a landmark order for two wheel de-trenching grapnels.

They will be deployed from subsea cable repair vessels in France. The products will be delivered to a long-standing DLM customer in May.

DLM is already renowned for the manufacture and supply of running line monitors (RLMs); saddleback monitors (SBMs), used in pre-lay grapnel run (PLGR) and route clearance operations to measure line tension; load pins; and load cells that capture data as tension is applied to the winch rope towing the grapnels. However, these products are unique in that they are specifically for recovering cable that is buried in a seabed.

A wheel de-trenching grapnel (or WTG) is used to de-trench cables buried at depths of greater than 0.5m. The WTG is one of the most robust grapnel products available; it can be used in harsher seabed environments, for example, rocky conditions, but also in soft and crumbly (friable) seabeds, where the addition of the wheels will help to maintain penetration. The end user operates a fleet of cable repair vessels, but the solution will be of interest to anyone that completes repair work on laid cables.

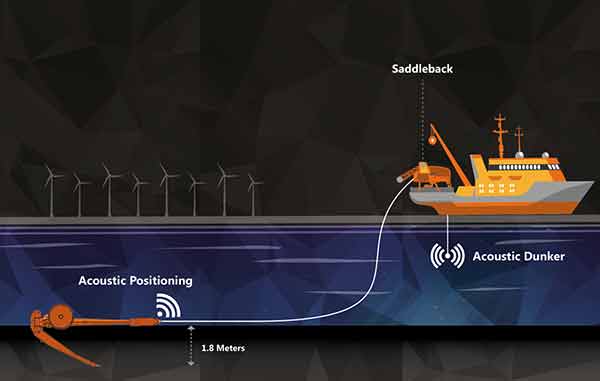

The customer knew of the concept, but asked DLM if it could design a version that was suitable to penetrate 1.8m into the seabed. Previous designs were only suitable for 1.1m. Notably, DLM is the only company that offers a 1.5m and 1.8m fluke (a prong-shaped tool that penetrates the seabed) version of the product.

Chris Scrutton, technical manager at DLM, said: “We will never sell lots of these products, as there is a limited number of cable laying ships in the world capable of handling them, but the fact that we have upgraded the design for the 1.5m and 1.8m penetration shows that we have one of the best offerings on the market and this will appeal to any cable ship owner in need of this type of equipment. Further, it reinforces the engineering prowess for which we are renowned. This type of product represents a steady source of income for us—and we can design them quickly and confidently. We completed a feasibility study for the client prior to them placing an order to ensure that the product would be suitable for the application.”

The de-trenching grapnels will be used repeatedly in a suite of cable repair equipment. They can also be used for plough assessment surveys to assess what the industry calls “plough-ability” of the seabed, providing important information prior to laying a new subsea cable. In other words, this deciphers how tough the seabed conditions are and what equipment will be required to lay a new subsea cable.

Scrutton explained that traditional versions of these products would use wheels and foam-filled tyres. DLM effectively upgrades the wheels to a newer method of rubber blocks in place of tyres, allowing for individual rubber blocks to be replaced in the event of damage. There is also an option to fit load monitoring equipment to the shear pins to record the loads seen when in operation. This data is recovered when the grapnel is back on the deck of the ship again.

He added: “This end customer has had three ships newly built, which serves as a barometer of the buoyancy in this marketplace, driven by the constant increase in offshore wind energy.”

Contact for editorial enquiries: Carly Collins, carly@dlm-uk.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.