Fiberglass vs Steel Rebar: Why does the construction and engineering world turn to composite materials as a steel alternative?

Strategic-thinking businesses opt for industry transformation, not just a product replacement.

The growing demands in the construction sector require innovative technological solutions. Conventional reinforcement materials give way to modern substitutes.

Glass Fiber Reinforced Polymer rebar, or GFRP rebar, is a composite reinforcement material. Manufactured of glass fibers embedded in a polymer matrix, GFRP offers impressive mechanical properties and superior performance in challenging environments. Lightweight, high strength and resistance to corrosion are principal qualities of FRP products that make them an attractive choice for various applications.

The quality and performance of GFRP rebar depends on two critical production factors:

The advanced manufacturing technologies ensure precise fiber alignment and consistent resin impregnation. Automated quality control and scalable production capabilities help reliable GFRP rebar manufacturers address the growing market demand and meet industry-specific quality requirements.

Light Weight. FRP rebar weighs ¼ of steel rebar. The lightweight nature of composites results in easier handling, lower labor and transportation costs, and faster installation. This aspect is particularly important for projects in remote and/or challenging regions.

Corrosion resistance. Unlike steel, GFRP isn’t prone to corrosion when exposed to high humidity, moisture, chemicals, or salts. Composite rebar doesn’t deteriorate or rust; hence, it is a preferable reinforcement option for marine structures, bridges, chemical plants, etc.

High tensile strength. GFRP surpasses steel in terms of strength in certain applications, particularly in harsh environments. That is why GFRP rebar is an excellent choice for projects that require high load-bearing capacity.

Enhanced service life. The non-corrosive nature of composite rebar ensures superior durability for reinforced structures. A longer lifespan translates into reduced maintenance and repair costs and overall lifecycle savings.

Non-magnetic and non-conductive properties. GFRP rebar is suitable for reinforcement in environments where electromagnetic interference should be avoided and for structures with sensitive equipment, such as power stations and medical facilities.

Sustainability. Longer service life, low maintenance, and reduced transportation emissions result in the lower carbon footprint of construction projects.

The technological shift in reinforcement materials from traditional steel to GFRP rebar is backed by extensive research and proven results. The growing demand for a sustainable and durable alternative to steel sets GFRP rebar as a standard reinforcement option for infrastructure projects in regions with aggressive conditions.

Different industries benefit from composite materials’ potential. For example, in renewable energy sectors, FRP enables more durable and resilient solar and wind infrastructure installations. In the telecommunication sector, FRP-reinforced structures are less susceptible to environmental degradation. Civil engineers opt for fiberglass reinforcement to ensure durable urban infrastructure that withstands severe climate conditions.

Composites represent a strategic instrument for businesses that seek new construction approaches. Besides traditional applications, GFRP opens new prospects for project development in sectors where conventional reinforcement fails to address complex challenges.

When business owners shift from steel to GFRP rebar, they gain a competitive advantage in the market due to:

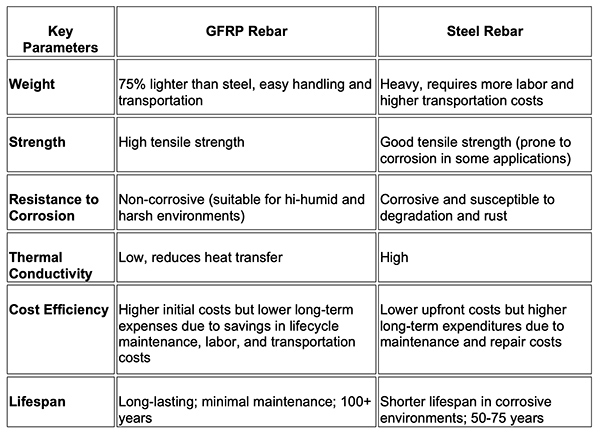

The chart below compares the key characteristics of GFRP and traditional steel rebar:

As a result, we see that GFRP rebar excels in aggressive environments and represents a superior option for high-corrosion, marine, and chemical projects. Fiberglass reinforcement has proved its cost-efficiency across multiple infrastructure projects due to its longer service life and low maintenance costs.

The high demand for GFRP rebar in the modern construction landscape presents a new challenge for enterprises. Now the focus of attention has shifted to reliable GFRP rebar suppliers. One of the industry leaders is Composite-Tech.

In the past 10 years, Composite-Tech has perfected its FRP rebar production lines. In partnership with leading universities and regulators, the company has significantly improved the GFRP rebar manufacturing process and earned the reputation of a global supplier of FRP production equipment.

The trend for smart and sustainable construction practices put composite products in the limelight. GFRP rebar offers apparent advantages in terms of strength, weight, resistance to corrosion, and service life. Forward-thinking businesses understand that fiberglass reinforcement meets the demands of the modern construction landscape.

In partnership with Composite-Tech, construction and engineering companies can work up new markets and make their projects more sustainable and cost-efficient.

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.