Newly expanded capabilities, advanced configuration options, and a significant pricing reduction.

SAN FRANCISCO – Fictiv, the operating system for custom manufacturing, today announced a series of exciting new updates to its 3D printing service in order to meet the needs of its industrial customers’ most demanding additive manufacturing programs.

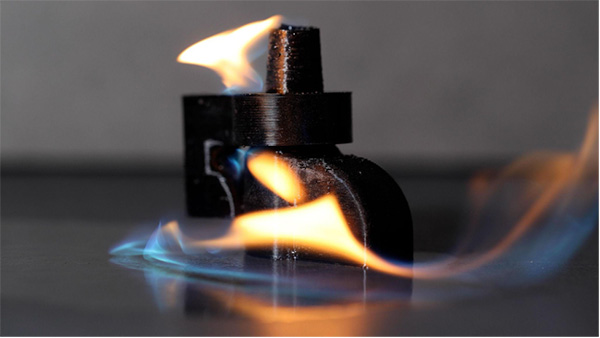

Fictiv now offers 14 new 3D printing materials for advanced engineering applications, including high-temperature materials such as Ultem 9085, biocompatible materials such as ABS-M30i for surgical guides and medical devices, and a suite of SOMOS materials for optical clarity and water resistance. The new materials are ideal for a wide variety of use cases across automotive, industrial, consumer products, and medical industries, for production quantities, functional assemblies, jigs and fixtures, and much more. All of these materials are available today for on-demand purchase in the USA via Fictiv’s digital manufacturing platform.

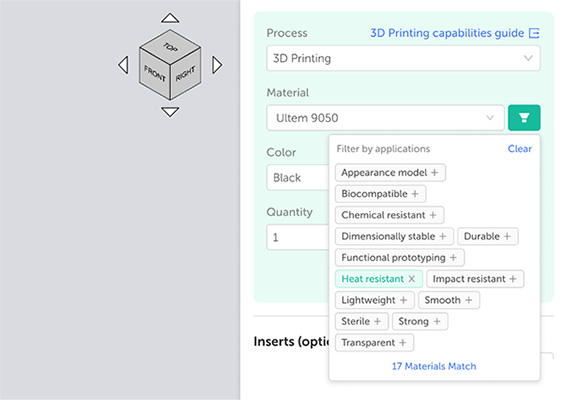

Additionally, customers will enjoy new online quoting features for 3D printing via the Fictiv platform, including expanded lead time options that allow customers to select from three different production times for improved flexibility and pricing, new configuration options for infill density and threaded insert specification, and improved filtering for material selection by application.

Available at the end of October, customers will have access to Carbon Digital Light Synthesis™ (Carbon DLS™) 3D printing technology via the Fictiv platform. Carbon DLS™ printing stands out for its rapid speed, high-resolution capabilities, and diverse range of materials, making it an ideal choice for scalable production across a range of industries.

Expanded partnerships with cutting-edge additive manufacturers, including Jabil Additive (NYSE: JBL), has opened up new production-level 3D printing solutions for ordering hundreds to thousands of parts with industry-best prices. With Fictiv’s digital supply chain infrastructure and quote-to-order platform, it’s never been easier to access the best additive manufacturing technologies to fuel product innovation in all stages of development.

“We are committed to providing our customers with industry-leading 3D printing solutions for R&D as well as high-volume production needs for new product introduction,” said Riley Hall, Director of Additive Manufacturing at Fictiv. “With this expansion, our customers will not only be able to source parts with cutting-edge lead times for 3D printing, with more options than ever, they’ll also have access to all of this at an incredibly cost-effective price point.”

“We are thrilled to partner with Fictiv to provide customers with streamlined access to the highest quality industrial 3D printing solutions,” said Curt Miner, Business Development Manager at Jabil. “Fictiv’s technology platform combined with our robust additive manufacturing capabilities enables a level of speed and scale this industry has never seen before.”

To learn more about Fictiv’s 3D printing solutions, visit the company’s website.

About Fictiv

Fictiv is the operating system (OS) for custom manufacturing that makes it faster, easier, and more efficient to source and supply mechanical parts. Its intelligent OS, supported by best-in-class operations talent, orchestrates a network of highly vetted and managed partners around the globe for fast, high-quality manufacturing, from quote to delivery. To date, Fictiv has manufactured more than 25 million parts for early-stage companies and large enterprises alike, helping them innovate with agility and get products to market faster.

Media Contact:

Courtney Tolbert

5W Public Relations

fictiv@5wpr.com

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.