Members of the supply chain can reduce the impact of the bullwhip effect by taking the appropriate steps and implementing the right tools.

By Peter Edlund, VP Product Management, TrueCommerce

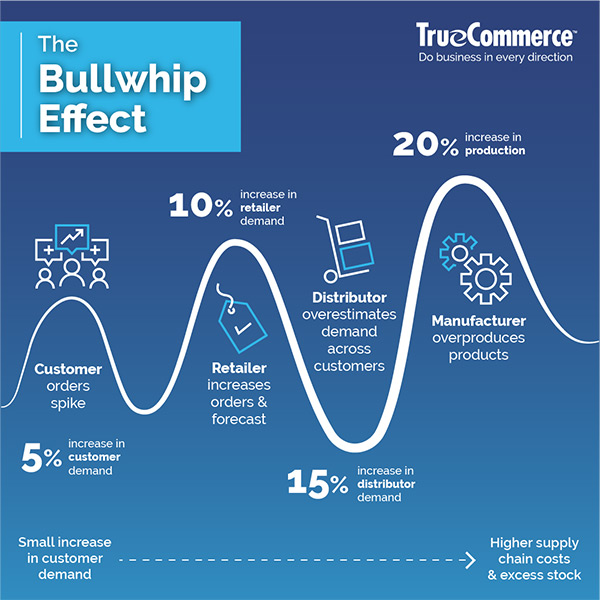

In a supply chain, the bullwhip effect occurs when each party gradually escalates an initially small spike in demand. Each member of the supply chain overcompensates for this demand with excess product, leading to increased production, inaccurate demand forecasting, and inconsistent inventories. Let’s look at the impact of the bullwhip effect on supply chain management and what you can do about it.

The bullwhip effect is the distortion of demand and increased volatility that occurs as forecasts and orders move from the retailer up to the manufacturer.

When a spike in demand occurs, each party in the supply chain adds additional products to their orders to act as a buffer. When one party does this, it serves the necessary function of ensuring in-stock products. However, when everyone does it, the result is inaccurate forecasting, stock hoarding, overstock inefficiencies, and out-of-stock products later.

This amounts to periods of both overstock and low stock and unpredictability throughout the supply chain.

The impact of the bullwhip effect on supply chain management is significant and includes:

If you can keep the bullwhip effect to a minimum, you can ensure more predictable and profitable supply chain management. Here are some tips on how to reduce the bullwhip effect.

The bullwhip amplifies because supply chain members don’t have a full picture of why buyers are increasing demand. Improving visibility across the supply chain can help everyone see the context of demand changes.

Some tools that help include:

Predictive analytics use advanced algorithms and calculations to interpret historical trends and current events and generate forecasts of future trends. These programs can range from simple to complex, many using artificial intelligence (AI), but all of them rely on high-quality data.

Robust collaboration is one of the best defenses against the bullwhip effect, which generally comes from disconnected inventory practices.

Long lead times can exacerbate the bullwhip effect, with products arriving far after they’re needed and becoming overstock. Reducing lead times across the board and placing orders when demand is high can mitigate bullwhip issues. Correctly calculating lead times can help ensure better order fulfillment and less customer disappointment.

If you frequently run promotions or discounts, you may be disrupting typical buying patterns and have more trouble predicting demand. Evaluate your stance on these promotions and see if they might be causing more interruptions than benefits.

The bullwhip effect can quickly get out of control and hit every part of the supply chain with adverse effects. Visibility and transparency are some of your best resources for fighting the bullwhip effect, and the right platforms can help you find both. Visit www.truecommerce.com to learn more.

Peter Edlund is VP of Product Management, retail at TrueCommerce with over 25 years of experience helping organizations in retail and consumer packaged goods (CPGs) leverage B2B integration throughout their supply chain by using data standards and technology to automate complex order and fulfillment process.

Peter is actively involved in industry trade and standards groups such as NRF, GS1 and RVCF. In addition, he is currently an advisory board member to the Center for Supply Chain Research at Lehigh University where he actively participates in industry research.

Peter is a veteran of the U.S. Navy and attended Central Texas College and Embry Riddle Aeronautical University where he studied aviation and business management.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.