Advanced material semiconductors enable low-cost, low-carbon edge and item-level intelligence for real-time supply chain visibility.

By Richard Price, CTO, Pragmatic Semiconductor

In recent years, global supply chains have been subjected to multiple disruptions caused by factors such as rapid inflation, geopolitical uncertainty, extreme weather and the lasting impacts of the COVID-19 pandemic. More than ever, this unprecedented period of volatility has underscored the need for supply chain resilience and efficiency.

But how can companies best mitigate risks and reduce disruptions?

A multifaceted approach is essential. A diversified supplier base enables organizations to reduce dependency on any one source and be better prepared to tackle location-specific disruptions. Bringing manufacturing closer to end markets can also reduce reliance on global transportation routes. However, perhaps the most transformative solution lies in the integration of advanced technologies.

Item-level intelligence gives the ability to accurately track goods in transit in real time – something that’s particularly important when delays or shortages occur. There are, however, several challenges to address before ubiquitous connectivity can be achieved – specifically, cost, speed of deployment and environmental impact.

Smart functionality typically relies on silicon-based microchips, which can be expensive and time-consuming to produce, taking months – if not years – from conception to delivery. This makes them more suited to high-performance applications where long lead times are no issue and rapid customization is a not a requirement.

Sustainability is also an issue. Production of these chips can use vast amounts of energy and water, and up to 30 different process gases, many with considerably higher global warming potential than CO2.

However, new developments in non-silicon semiconductors – chips based on advanced materials – offer promising solution to these challenges, while unlocking the potential for implementation at scale.

Unlike traditional silicon chips, advanced material semiconductors allow for simpler production processes at much lower temperatures. This significantly reduces consumption of energy and water, as well as harmful chemicals, making sustainable, item-level intelligence a reality.

The reduced number of process steps also enables end-to-end production at a single location. This drastically improves turnaround times – taking designs from tape-out to delivery in just a few weeks – while also reducing cost, opening new use cases and bringing item-level intelligence where it wasn’t possible before.

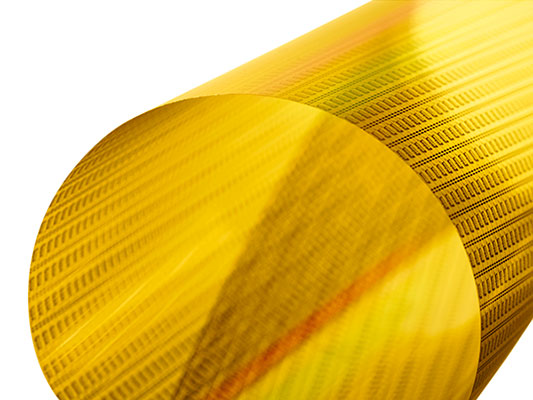

These advanced material chips are also ultra-thin and physically flexible by nature, making it possible to deploy them almost anywhere, from clothing and textiles to bottles or coffee cups. When embedded directly into packaging, they don’t encroach on product branding, can’t be covered or replaced, and are robust enough to withstand the rigours of transportation.

When combined with sensors within RFID tags, advanced material microchips provide end-to-end, real-time visibility of individual items as they pass through the supply chain. This level of transparency allows businesses to monitor location and movement – reducing the risk of loss or theft and identifying bottlenecks. Transit conditions such as temperature and humidity can also be tracked, ensuring that products remain in optimal conditions and quality control is maintained.

By monitoring individual items, rather than relying on aggregate stock data, the likelihood of overstocking or stockouts is reduced. Furthermore, the rapid identification of delays – whether due to production slowdowns or transportation issues – means corrective actions can be taken quickly to minimize disruption.

Beyond optimizing supply chains, item-level intelligence also plays an important role in the consumer experience. From providing real-time visibility into order status, to tailored content served up at the tap of a smartphone, consumers can receive a personalized experience that builds customer loyalty.

And for industries like pharmaceuticals, luxury goods, and electronics, this item-level intelligence plays a crucial role in verifying product authenticity and preventing counterfeiting. By embedding unique, trackable chips into products, companies can improve consumer satisfaction and reduce risks to health.

In short, the future of supply chain management lies in low-cost, low-carbon item-level intelligence. Through advanced material chips, this is becoming more accessible, sustainable, and scalable. This technology not only provides businesses with unprecedented visibility and control, but also supports more efficient, responsive, and environmentally responsible supply chains.

As businesses continue to face evolving challenges and market demands, adopting item-level intelligence will be key to building supply chain systems that are better equipped to navigate the future.

About the Author:

Richard has over 25 years experience in the development and commercialization of a wide-range of new technologies based on novel processes, materials and flexible electronics. Richard has a BSc and PhD in Chemistry from the University of Durham. He is inventor/co-inventor on over 25 patent families. Richard is a non-executive director at the Henry Royce Institute – the UK’s National Institute for advanced materials research.

Read more from the author:

Direct Commerce, October 2nd, 2024: Flexible intelligence: a new route to combat counterfeiting

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.