November 12, 2018

by Hailey Cheng, WayKen Marketing Manager

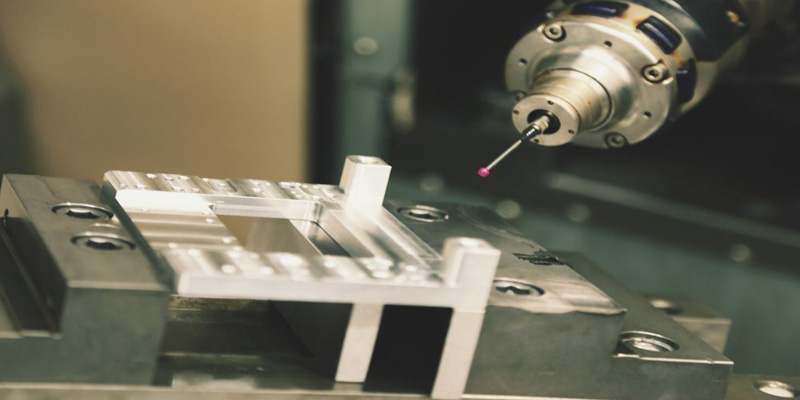

Precision CNC machining is a procedure which involves the removal of raw materials from an object to create a small end product with the use of cutting equipment, latest technologies, and human engineering to match all the precision requirements. For your business to survive in this modern era, you must stick to the ever-changing trends in the world of technology like precision CNC. Companies that deal with the production of machined parts will also subcontract precision machining services.

CNC Machining is a procedure used in the production sector which involves the use of computers or advanced technology to operate mechanical equipment. Some of the machinery that can run using this type of technology include grinders, mills, routers, and lathes. CNC is the acronym of Computer Numerical Control.

A special software and other control equipment are some of the things that make precision CNC machining possible. Precision CNC can be used in the production of both plastic and metal parts. Initially, a computer-aided design commonly referred to as the CAD is created and before the program is loaded into the system and an operation test is carried out to ensure there are no challenges. Due to the high precision levels that are required, CNC machines are usually used to make sure the finished product meets the required dimensions.

There are several instances when you may require precision machining services. You should look for the right shop if you want top quality services. One thing you should look out for is the equipment in a specific company. The best companies have state of the art equipment for this kind of task. This should include both hardware and software equipment that can be of great significance for precision CNC applications. A good precision machine shop will provide its customers with a stock of what they have to offer by listing down the available equipment. You also need to look at the quality of the services provided by a specific company.

A good company should put in different measures to ensure the precision machining services they offer is of top quality. This can only be possible when they use some of the best precision CNC tools which are certified by the relevant standards body. They should also take their clients through some of the steps in this procedure to ensure everything meets their requirements. You can compare the production costs for the different manufacturers. Rates may vary from one company to another depending on various factors.

You should put the quality of the precision machining services offered into consideration as you compare the costs. The precision CNC machining company you want to choose should be useful when it comes to delivery. Are they able to finish your task on time? Will they produce parts that meet your requirements? Putting all these into consideration will help you settle for the best precision CNC shop, and you will get quality parts.

There are several benefits you get to enjoy with precision CNC machining. One is that the chances of making errors are very minimal. The precise specifications are usually keyed in before the precision CNC machining process begins. Having this procedure carried out by human employees will lead to more errors, and you may not give your client the desired final product. You will also experience increased production speeds in this procedure. It involves the use of a special computer program that can interpret a design and respond very fast.

CNC machines can work very fast compared to human hands over a long period which is very different when using human employees. There is minimal waste produced when it comes to precision CNC machining. Various companies are working hard to implement different waste reduction measures. Precision CNC machining can help reduce all the waste. This waste can be in the form of time, money and resources used.

All the tasks will be carried out efficiently to make sure all the material is utilized as required. You get to save a lot of money in precision CNC compared to other procedures or even using human labor. The costs you would have incurred when it comes to paying your employees will reduce significantly. Precision CNC machining will guarantee you the consistent production of quality items. This is because of the level of accuracy in CNC machines.

Engineers have the chance of testing a specific prototype before starting the manufacturing process. Doing so is essential because it guarantees the production of parts that meet the specifications of a particular client. How about you try this machining procedure for accurate finished parts.

Contact:

Tel: 86 0755 2373 1920

Email: hailey@waykenrm.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.