How Zenni Optical switched from manual fulfillment of eyeglasses to a fully automated solution.

By Simon Goh, Director of Distribution and Facilities at Zenni Optical

Zenni is one of the top four online eyeglass retailers worldwide, selling 6.5 million pairs annually – 6 million of them in the U.S. market alone. Our mission to make prescription eyewear affordable and accessible to everyone seems to be resonating with consumers — we just celebrated our 20th year and have doubled our sales in just the last four years.

The busy packing and shipping operations at two distribution centers determine whether we will live up to our reputation for excellent customer service, which has secured us a spot on Newsweek’s list of America’s Best Customer Service for five consecutive years.

Until recently, we had a fully manual process in place for shipping eyeglasses to our US customers. Our distribution workers placed each pair of glasses into a signature translucent blue Zenni clamshell case, and then inserted the case into a tabletop mechanical bagging machine, which dropped it into a labeled poly bag for shipping. It’s a slow and mind-numbingly tedious process — and that makes it prone to error.

If just one item scans out of sync with the customer order and ends up in the wrong bag, we will certainly have an unhappy customer squinting through incorrect lenses — and then a product return, a costly replacement product, and the loss of invaluable customer trust. Each month, we were shipping anywhere from 5 to 30 glasses to the wrong customer, and we knew we have to improve.

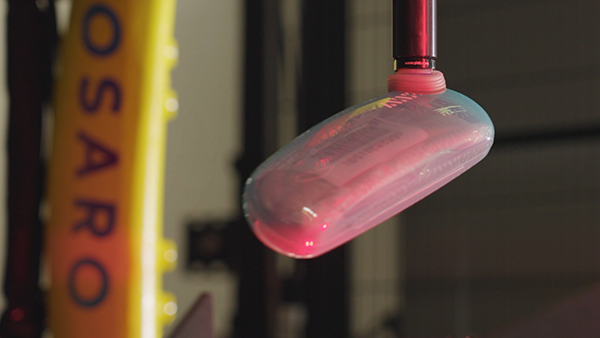

We zeroed in on automating the last step of the process: ensuring each glasses case ends up in the correct poly bag. To assist us, we turned to San Francisco-based robotics expert OSARO. Their team performed a deep-dive assessment of our multi-step process and concluded that performance gains could be achieved by using a robot to pick up each eyeglass case, read the barcode within the case, and ensure it ended up in the correct bag.

The system we’ve deployed comprises a FANUC M-10 robot equipped with OSARO’s SightWorks vision and control software, a Pregis Sharp automated bagging machine, Cognex DataMan barcode scanners, Framos cameras to guide the robot, and Smart Vision lighting. Systems integrator NPSG Global constructed the physical infrastructure with OSARO’s technical team.

Along the way, there has been a lot of learning — for the robots and for our team. Blyn Prokopowich, our shipping supervisor, recounts her experiences: “OSARO worked side by side with us to ensure knowledge transfer. They actively responded to all our questions and requests. I’ve seen my team change. They are very, very excited about this challenge. Learning new skills is good instead of doing repetitive motions every day. The skills give them confidence.”

Certainly, there were some obstacles. Our blue Zenni cases stymied several scanner-makers whose equipment was unable to read barcodes through the translucent plastic case. After some experimentation, OSARO and Cognex came up with a custom lighting solution. Another problem: printer lines or wrinkles in the shipping labels sometimes made it impossible for postal services to track the item during shipping – something our customers expect so they can track their purchases in transit. OSARO worked with Pregis to install a barcode verifier that alerts the team whenever a printed label is not trackable.

The final production system has demonstrated a 50 percent throughput increase and enables two people working with the robot to perform work that previously required three people – but much more accurately. With robots handling a repetitive task, we were able to cut the number of steps needed to process a pair of eyeglasses for shipping from five steps to two steps, making everyone more productive.

The new robotics system delivers 99.9% accuracy by reducing most of the risks inherent in manual processing and eliminating all the manual errors. The overall increase in productivity was due not only to fast, consistent throughput by the robot; it now takes fewer people to process shipments, which means we can assign some employees to other, more interesting, tasks that still require human intervention.

Today, each robotic system can pick, scan, bag, and label up to 410 eyeglasses per hour. The average pace can hover closer to 350 per hour when downtime to replenish bags or maintain the system is factored in, but the system’s machine learning is also expected to continuously improve performance over time.

With seasonal surges sometimes creating the need to process up to 450,000 units in a single month, robots provide valuable flexibility. They can work longer than people, allowing us to redeploy our team to other tasks that still require human intervention, such as unpacking boxes or processing returns.

Our workers seem to like it, too. Those that used to spend their workdays picking up eyeglass cases and putting them in bags are now monitoring the robots. It’s much less tedious work and offers them new opportunities to acquire technical skills and expand their career horizons. Minjie Hu, who just completed training as a robot operator, says, “Managing the robot is easier and better than stuffing packages. Learning new skills is better.”

Sure, there are a lot of media stories about robots taking people’s jobs, but Zenni has absolutely no plans to lay off anyone. In fact, automation just might help retain jobs here at home. The US has higher labor costs, but with robots you can reduce the difference between the U.S. and developing countries.

ABOUT THE AUTHOR

Simon Goh is director of distribution and facilities at Zenni®, which pioneered the online eyewear industry in 2003 with a mission to make prescription eyewear affordable and accessible to everyone. Based in the San Francisco Bay Area, Zenni offers men, women, and children the freedom to express their personal style through high-quality prescription and protective eyewear curated with a sense for fashion and incredible selection. Connect with Simon on LinkedIn.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.