Improved MMW attenuators drive advancements for electronics manufacturers, paving the way for next-gen wireless tech.

The move up the electromagnetic spectrum (EM) into millimeter waves (MMW) is proving to be a double-edged sword. System designers eager to leverage wider bandwidths and incredibly high data throughputs must also contend with a host of new challenges. Of amplified importance – particularly between 75-330 GHz – is the issue of attenuation.

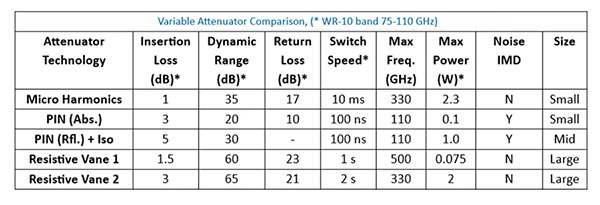

When the strength or magnitude of a radio frequency (RF) signal must be reduced, attenuators are traditionally relied upon. They are especially useful for signal leveling or switching applications. At frequencies above 50 GHz, two electronically tunable variable attenuator technologies are most often employed: PIN diode and resistive vane attenuators. However, both come with substantial drawbacks which have led engineers in search of alternatives.

As part of that pursuit, component manufacturers returned to research published in 1961 on Faraday rotation. In a paper entitled Broad-band Isolators and Variable Attenuators for Millimeter Wavelengths, C.E. Barnes laid out a theory for utilizing Faraday rotation in MMW applications. At the time, several RF engineers pursued the theory, but no one was able to achieve the desired results. Now, with the demand for alternative MMW attenuators increasing, manufacturers are finding ways to successfully deploy a third option for MMW voltage variable attenuators.

PIN diode attenuators are a popular choice for signal attenuation at lower frequencies due to their relatively low cost, compact size, and fast switching speeds – often as quick as 100 ns. These devices operate by applying a variable bias voltage to the PIN diodes, which controls the level of signal attenuation.

However, as the operating frequency increases beyond 60 GHz, several performance issues become apparent:

These limitations make PIN diode attenuators increasingly ineffective for mm-wave applications, prompting the need for alternative solutions that can handle the demands of these high-frequency environments.

On the other hand, resistive vane attenuators have long been the go-to technology for high-frequency applications, offering a much flatter frequency response and significantly higher dynamic range compared to PIN diode attenuators. These devices utilize a mechanical actuator to insert a resistive vane into a waveguide, gradually attenuating the signal.

While this approach works well in controlled lab settings, it poses several challenges in real-world applications:

Given these disadvantages, there is a clear need for a solution that combines the high-frequency performance of resistive vane attenuators with the compact size and speed of PIN diode devices.

Faraday rotation attenuators utilize a magnetic coil to produce a variable magnetic bias field in a ferrite rod. A Faraday voltage variable attenuator could, in theory, offer full waveguide band operation and high-power handling compared to other technologies.

As an example of what is possible, Micro Harmonics Corporation (MHC) recently developed the first two lines of mm-wave attenuators in both the W band (WR 10, 75-110 GHz) and D band (WR 6.5, 110-170 GHz) based on the Faraday rotation principles. Their approach leverages the Faraday effect to rotate the RF signal’s polarity, directing it into a fixed resistive layer embedded in a ceramic cone.

Unlike resistive vane attenuators, Faraday voltage variable attenuators achieve signal attenuation without any moving parts, leading to several key advantages:

One potential drawback when using magnets and ferrite in a Faraday attenuator is the issue of repeatability due to the ferrite’s magnetic memory. This means that simply shifting from one current level to another does not always guarantee the same attenuation when returning to the initial level. However, extensive studies have shown that this can be mitigated effectively by forcing “a reset” on the attenuator by simply bringing the current down to zero before adjusting it back to a desired voltage. This process can be executed rapidly, maximizing repeatability without significant delay.

Stray magnetic fields can also affect the performance of Faraday technologies. To overcome this, manufacturers have found that incorporating external magnetic shields around the attenuator ensures stable operation even in magnetically noisy environments.

Faraday rotation-based attenuators are particularly well-suited for applications in telecommunications, radar systems, and test and measurement equipment operating at mm-wave frequencies. Their combination of high dynamic range, low insertion loss, and compact size makes them ideal for field use in aerospace and defense systems, where both performance and portability are critical.

Faraday attenuators are also beneficial in research and development environments, where precise signal control and rapid adjustments are necessary for experimental setups involving high-frequency components.

For more information contact Micro Harmonics: 540.473.9983 or visit www.MicroHarmonics.com

A warm welcome to our guest Didi Caldwell, CEO of Global Location Strategies (GLS) and one of the world’s top site selection experts. With over $44 billion in projects across 30+countries, Didi is reshaping how companies choose where to grow. Here she shares insights on reshoring, data-driven strategy, and navigating global industry shifts.