Six out of ten businesses target geographic diversification of manufacturing supply chains to build resilience.

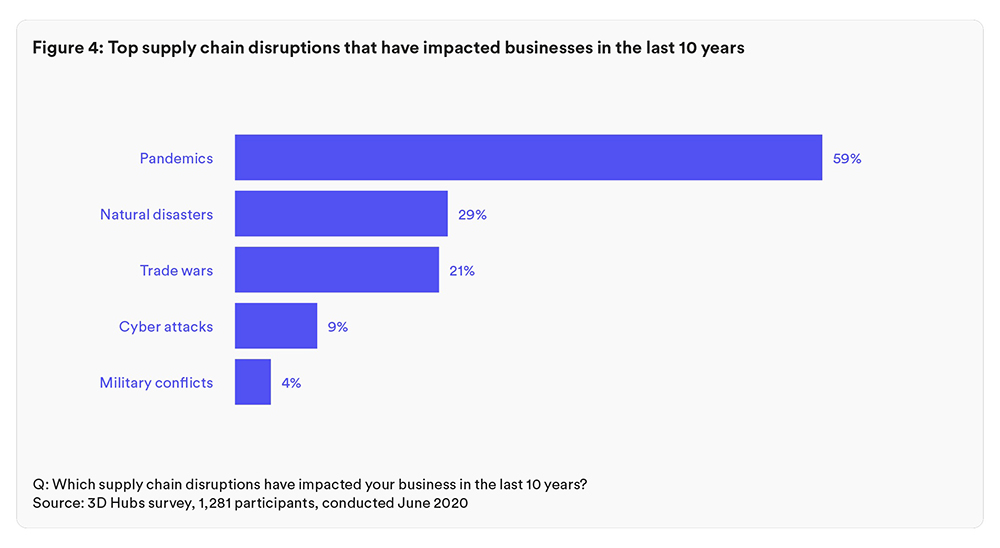

Amsterdam – According to the Supply Chain Resilience Report 2020 from 3D Hubs, the global leader in distributed manufacturing, cybersecurity issues have affected less than 10% of firms over the past 10 years, compared to 60% that have suffered directly as a result of COVID-19 disruption.

In 2020, the pandemic has emerged as the most potent threat to economic growth, more than trade sanctions, natural disasters and cyberattacks combined. Over 96% of global companies are now planning to take measures to boost the resilience of their manufacturing supply chains. However, more than half (52%) admit they are yet to embark on that journey. As businesses develop long term strategies, over 59% of companies say geographic diversification of their supply chains is the most effective way of building resilience.

The 3D Hubs Supply Chain Resilience Report 2020 includes insights from an industry survey of 1,281 professionals, its own database of 36,000+ companies, and 240 global manufacturing partners.

About 3D Hubs:

3D Hubs is an online manufacturing platform that provides engineers with on-demand access to a global network of manufacturing partners. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Founded in Amsterdam in 2013, 3D Hubs has raised over US$30 million and produced more than 5 million parts, using various manufacturing technologies, including CNC machining, 3D printing, injection molding and sheet metal fabrication.

The full report will be available to download for free here on July 29th.

3D Hubs Contact:

Tess Roberts | Communications Manager | press@3dhubs.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.