Revolutionize your sheet metal operations with LEAN Storage Systems.

If you run a metal fabrication shop, you know the struggles of dealing with sheet metal inventory. Unloading pallets, burying material, damaging sheets while moving them – it’s a constant battle to keep things organized and undamaged. But what if there was a better way? Imagine this: Your raw sheet metal material comes pre-loaded onto returnable cartridges from your trusted local service center. No more unloading pallets and risking damage. The cartridges are transported safely to your shop and easily loaded into a high-density storage system, keeping everything neatly organized and accessible. When you need material for a job, just pull the cartridge from the storage system. The sheets stay flat, undamaged, and perfectly aligned. No more digging through stacks trying to find what you need while your machines sit idle. As the cartridges empty, your service center picks them up and reloads them, continuously circulating the same reusable cartridges. It’s a closed loop system that eliminates wasted time, damaged material, and employee frustrations.

Let’s face it – traditional pallet racking and cantilever racks are inefficient for sheet metal storage.

Material gets buried, FIFO (first-in-first-out) processes break down, and your shop floor becomes a maze of precariously stacked inventory. The cartridge system combined with high-density storage racks is revolutionizing the industry. These vertical storage solutions maximize your floor space while keeping everything organized and easily retrievable.

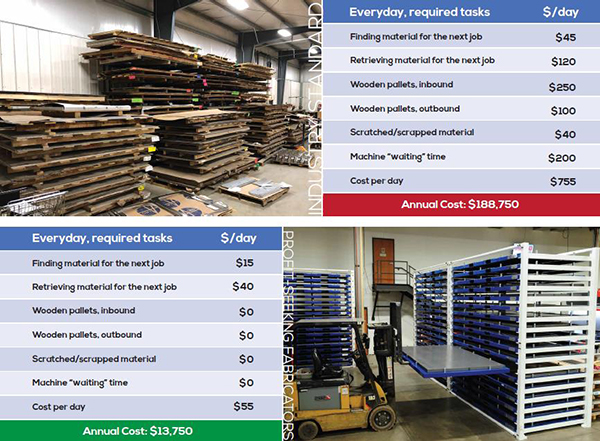

Making the switch to LEAN cartridge systems and optimized storage might seem like an investment, but the return is surprisingly fast. By eliminating wasted time, reducing damage, and maximizing efficiency, most shops see a full ROI within a year. Think about the costs of having your expensive machines sitting idle while employees scramble to find and prepare material. Factor in replacement costs for damaged sheets. Add up the floor space being wasted on inefficient storage. The savings quickly outweigh the upfront costs.

If your metal fabrication shop is still relying on outdated pallet storage and material handling methods, it’s time to make the jump to LEAN High-Density Storage Systems. Stop letting your profits get buried under disorganization and inefficiency. LEAN Manufacturing Products offers turnkey solutions to streamline your inventory management. With their patented cartridge system creating buzz throughout the industry, you can join the ranks of fabricators taking their operations to the next level of lean productivity. Reach out today to learn more about how cartridge systems and optimized storage can transform your shop floor and maximize business growth year after year.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.