There are exciting new possibilities for AI & IoT in the health care and automotive world. But what about the world of operations? Are AI and IoT practical for manufacturing operations? Can they really impact outcomes in the manufacturing industry?

The manufacturing industry is undergoing massive transformation thanks to the collision of two worlds – the physical world (consisting of industrial equipment like pumps, motors, valves, boilers etc.) and the digital world (consisting of deep learning artificial intelligence algorithms, miniaturized sensors, high velocity sensor data streams and Industrial IoT). This fusion of two worlds is creating “digital twin” of electro-mechanical factory operations that impact tangible and measurable quality and yield outcomes. Here are three real world stories from the trenches about how artificial intelligence and IoT are powering the pathway to exponential transformations in industrial outcomes.

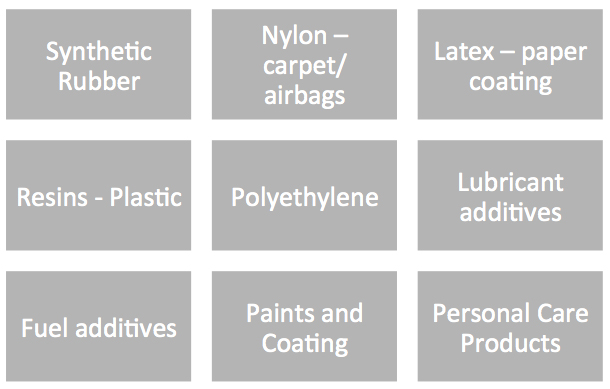

In North America, the majority of control loops controlling factory operations have not been tuned to reach optimal performance. During installation, the tuning parameters are left as the manufacturer defaults. When problems occur with control loops, people often tend to reduce the tuning parameters, as this is the quickest way to reduce instability. Flutura was recently involved in transforming the outcomes of a chemical manufacturer in Texas. One of the chemicals this manufacturer produces is Butadiene and it is used in manufacture of multiple products.

When a command has been given to a control valve for a new position, the behavior of the valve will vary depending on its position, its direction and the amplitude of the signal. Flutura used a deep learning powered product to scan through valve operations/stage and learned the correlation between valve positions, performance and quality of mixture in reactors. This algorithm was further tuned to create a valve health score that helped the maintenance and manufacturing teams to allocate precious resources to bottleneck valves.

Catalyst play a big role in the refinery industry. While making a catalyst, viscous fluid passes through heat exchangers, agers and post process towers before catalytic balls are formed. Once the catalytic balls are formed they are impregnated with metal like nickel or magnesium. One of the problems to solve in catalyst manufacturing is improving the yield of the catalyst. As a part of this process, about 1000 sensor tags across temperature, pressure and flow rates at multiple stages where captured. Deep learning is used to uncover anomalies in an unsupervised mode from the process sensors and early warning signals of quality failure were sent to plant operations to help take corrective action to improve yield of the catalyst.

Flutura was working with an electric glove manufacturer in Ohio who wanted to reduce defects in the process by 12 %. The glove manufacturing process consisted of six steps from pinning, dipping, rolling, chlorinating, drying and inspection, The deep learning algorithmic product analyzed data from sensors and lab data pools consisting of viscosity, solids in each processing tank, ambient humidity , tank temperatures and fluid discharge rates. The deep learning algorithmic product learned patterns in data and was able to predict future quality outcomes.

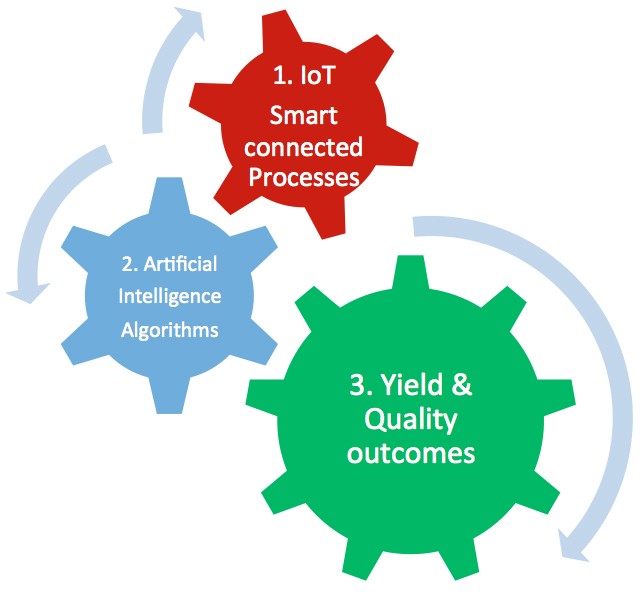

As can be seen from the above, AI & IoT would revolutionize smart connected operations in manufacturing. Manufacturers will need to embrace this new paradigm to stay ahead by pulling three specific levers :

As Darwin said “It is not the strongest of the species that survives, nor the most intelligent that survives. It is the one that is most adaptable to change.” Good luck as you adapt to the new world of IoT & AI.

Rick Harlow, EVP, Americas, Flutura Decision Sciences and Analytics

Rick Harlow, EVP, Americas, Flutura Decision Sciences and Analytics

Rick is executive Vice President, Americas for Flutura and is responsible for driving revenue for America and the IoT Vision for Flutura. Rick has over twenty years of artificial intelligence, advanced analytics and machine learning experience. He has held executive positions at companies such as Integron, Sprint, T-Mobile and Astradero.

Rick is experienced in product planning, strategy and implementation for large-scale, global industrial machine intelligence initiatives, and in leading world-class, cross-disciplinary teams to meet the requirements of successful industrial machine intelligence deployments. Rick is a member of Infragard. InfraGard provides members of the Critical Infrastructure community a means to share information to prevent, protect, and defend against hostile acts against Critical Infrastructure and Key Resources (CIKR).

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.