Vesconite side-tipper trailer bushings are finding success with one manufacturer doubling its orders.

Johannesburg – In a testament to the outstanding performance and reliability of Vesconite self-lubricating bushings, a prominent South African side-tipper manufacturer has doubled its monthly orders for side-tipper bushings.

This substantial increase in orders reflects the manufacturer’s confidence in Vesconite Bearings’ superior products, customer satisfaction and excellent pricing.

The manufacturer’s confidence in Vesconite self-lubricating bushings is further demonstrated by a noteworthy shift in its buying patterns. In the last year, the company has adopted a proactive procurement approach by placing blanket orders and securing monthly supplies several months in advance to ensure consistent stock availability. This strategic move acknowledges Vesconite’s importance as a key supplier of parts.

Vesconite self-lubricating bushings, known for their exceptional performance, are superior to materials such as nylon and bronze in this application.

Vesconite bushings are self-lubricating, a crucial benefit when dealing with abrasive materials such as sand during transportation. Unlike greased lubricants, which can turn gritty, forming an abrasive paste, Vesconite’s self-lubrication ensures long-lasting durability even in challenging conditions.

Another standout feature of Vesconite is its exceptional dimensional stability. This quality sets it apart from competing nylon parts, which are prone to swelling in moist environments. In contrast, Vesconite bushings remain unaffected, ensuring reliable performance in various operational settings.

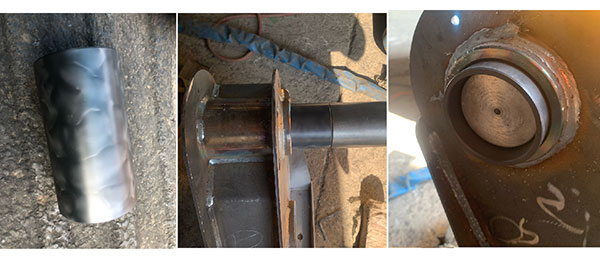

The Vesconite bushings in question play a pivotal role as the connecting point between the tipper body and the chassis of side-tipper trailers.

Each side-tipper body utilises two Vesconite bushings, with a bushing employed on each chassis pivot mounting, describes Tristen Wintershoven, Vesconite’s transport application engineer.

He notes that these essential pivot points enable side tippers to efficiently unload bulk materials, such as sand, gravel, or demolition debris, adjacent to the tipper truck using a hydraulic system that tilts the tipper body.

The preference for Vesconite self-lubricating bushings underscores the side-tipper manufacturer’s commitment to delivering high-quality, reliable equipment for the efficient unloading of bulk materials—a practice particularly valued in Africa’s mining, construction and road-building industries.

For more information about Vesconite Bearings and their range of self-lubricating bushings, please visit www.vesconite.com.

About Vesconite Bearings:

Vesconite Bearings is a world-leading manufacturer of low-friction, low-wear bearing materials for a range of industries, including the pump, agriculture, railways, mining, heavy transport, hydro, renewable-energy, earthmoving, marine and construction industries.

The Vesconite Bearings factory spans 20 000m2 and features advanced extrusion, injection-moulding and CNC machining facilities. Both standard stock (rods, bushings and plates) and high-quality finished parts are produced. The company is ISO 9001:2016 certified.

Contact:

Tristen Wintershoven

+27 11 616 1111

vesconite@vesconite.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.