GEP’s John Piatek shares how to remake supply chains as intelligent, agile, resilient, and cost optimized to drive competitive advantage.

By John Piatek, Vice President of Consulting, GEP, a leading provider of procurement and supply chain solutions to Fortune 500 companies

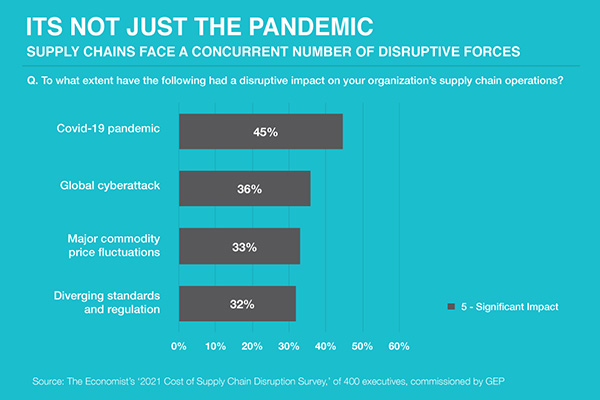

The pandemic has understandably dominated press coverage, which concealed for many that COVID-19 was only one of several extraordinary forces wreaking havoc with global supply chains. For some, COVID-19 has been an ‘easy out’ for executives and company board of directors. However, it really has simply masked years of under-investment in supply chains, which will constrain companies for years to come.

GEP recently commissioned The Economist to survey 400 U.S. and European C-suite leaders in supply chain, procurement, IT, finance, operations and strategy to better understand the cost to business from disruptions over the last 12 months and their priorities going forward.1

We found the majority of companies were unable to respond to both the supply-side and demand-side shocks. It resulted in double-digit revenue losses, increased operating costs, squeezed margins, disrupted manufacturing, and, perhaps most challenging, spikes in customer complaints and immeasurable long-term reputational damage.

While some leading firms such as Amazon and Apple have been lauded for their forward-thinking approach to supply chain, the reality is many firms do not regard supply chain as a source of genuine competitive advantage. For the past decade, companies primarily invested in their supply chain to cut costs and free up capital to invest in other parts of the business, such as R&D, marketing, etc., to drive revenue.

That’s all changed in the last twelve months, when companies found their supply chains are not fit for purpose. Companies now expect supply disruptions to become more common, driven by geopolitical risks — regional trade policy, instability, corruption — cyberattacks and commodity price uncertainty. Despite spending millions on ERP solutions, companies are ill-equipped to effectively manage their just-in-time, multi-step, multi-geography supply chains in the face of uncertainty, global warming, tariffs and trade wars, and national governments increasing control of natural and strategic resources and industries. As a result, more than half of the executives (54%) The Economist surveyed state that their organizations must make significant changes to effectively manage supply chain disruptions in the next five years.

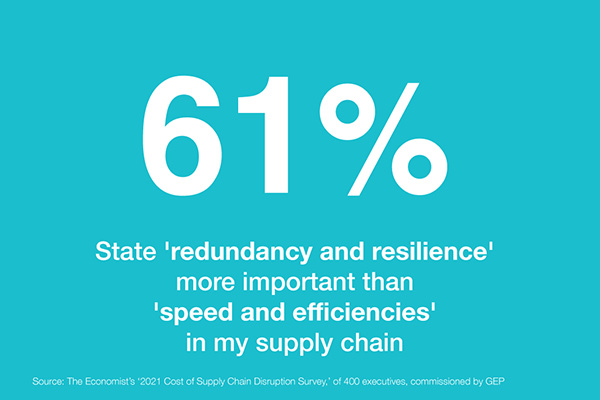

Signalling a major shift in strategy, sixty-one percent (61%) of executives agree that “redundancy and resilience in their company’s supply chain are more important than speed and efficiency.” Companies are now aggressively pursuing a range of tactical actions to mitigate the impacts of future disruptions, including strengthening relationships with existing suppliers, implementing permanent supply chain risk management teams and processes, accelerating investment in digital technology, and integrating supply chain and procurement more closely with finance and IT.

This is an extraordinary, once-in-a-generation, moment to remake your company’s supply chain as an intelligent, agile, resilient, cost optimized, and automated network to drive competitive advantage. To do it successfully, follow these six strategic imperatives:

About the Author

John Piatek is a vice president of consulting with GEP and co-leads the consumer goods and retail practice. John partners with leading Fortune 500 firms on strategy, supply chain and supply management initiatives. John is passionate about procurement transformation, growth strategy, performance improvement and cost reduction, end-to-end corporate transformations, and sustaining change.

[1] The Business Cost of Supply Disruption survey of 400 U.S. and European business leaders, published by The Economist’s Intelligence Unit (EIU) in February 2021

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.