As an essential agricultural crop and a highly versatile commodity here are some of the uses of cotton.

Cotton refers to the fiber found around the seeds of several species of the plant bearing the same name. Cotton is an essential agricultural crop and is cultivated in over 50 countries around the world. Tens of millions of tons are harvested every year. The value of the world’s cotton production is about USD$50 billion every year. Even though cotton isn’t a food crop, its influence in the economies of many countries and world trade cannot be overemphasized.

What is cotton used for? What makes it such a valuable raw material? Why is it the center of a huge global industry?

Cotton is a highly versatile commodity responsible for many end products in the market. Below are some of the uses of cotton.

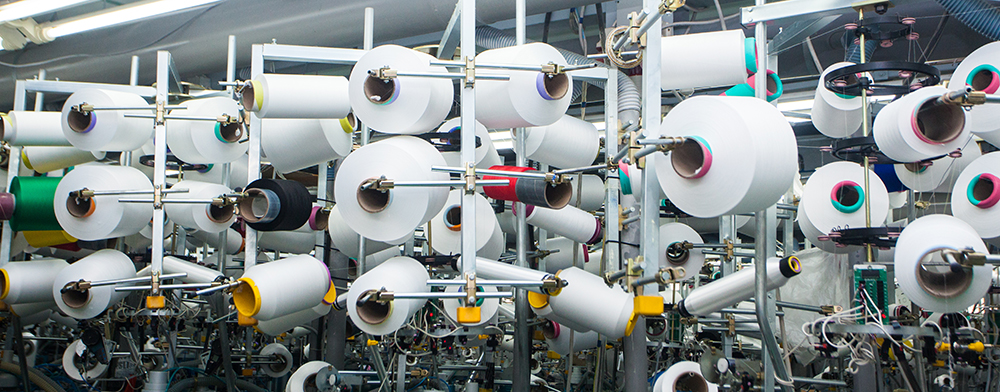

Cotton is the raw material for most types of fabric and textiles used for clothing and other commodities. Once woven, cotton turns into a velvet, corduroy, denim, velour, jerseys, flannel, and chambray.

For a long time, non-woven products featured human-made fibers almost exclusively. Today, cotton is used to produce softer and hypoallergenic top sheets, hygiene pads and underwear garments. Cotton is also a common ingredient in lotions, shampoos, and body washes.

Cotton fibers are also used to create swabs and cotton buds. These fibers can also be seen in the production of mattresses, furniture, automobile cushions, and even television sets.

Cotton is also present in unexpected products, like bookbinders, bandages, ropes, cords, and fishing nets. Furthermore, oil from cotton seeds makes products such as soap, cosmetics, and margarine.

Cotton grows in areas that experience long summers. Planting is best done in the winter so that the cotton ball ripens and the fibers expand under the warm sun. The ball splits, and the fluffy cotton bursts forth. The crop is now ready for harvesting, which generally involves picking cotton by hand. In developed countries, harvesting machines may be used.

Like any other huge manufacturing plants, the cotton industry affects the environment. The amounts of chemicals used in cultivating cotton crop are very high. By estimate, one pound of processed cotton requires 150g of chemicals in the form of fertilizers and pesticides to produce. There are also concerns about the poisons that remain in the soil and those washed into water bodies, which lead to eutrophication and wildlife poisoning.

Furthermore, the processing procedures employed during dyeing also use synthetic chemicals. Synthetic chemicals are not biodegradable, which means they stick around in the environment for a long time. These chemicals cause soil and water pollution. Additionally, they affect those who work in harvesting and producing cotton. Some of the common health concerns involved in manufacturing cotton include respiratory disorders, chemical poisoning, and many others.

The cotton manufacturing industry is profitable. The profits are unlikely to dip any time soon, especially with the steady increase in demand from the growing population. However, the industry also has a significant impact on the environment. Still, there’s promising research involving the development of a long-term solution by switching to organic cotton manufacturing from seeding process to distribution. Sustainable practices will reduce pollution and protect consumers from the chemicals that stay in the fabric long after production.

Freddie Jordan

Freddie Jordan has been a blogger for more than ten years. Freddie loves to write articles about technology, law, and real estate. Aside from making sure that his own blog is updated with different content, Freddie also submit articles to other websites.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.