PCB design teams can harness the power of AI to design electronics that are ready for manufacturing on the first try.

By Matthias Wagner, Co-Founder and CEO of Flux

Your team’s printed circuit board (PCB) may work as a prototype, but is it ready for mass production? Often the hardest part of hardware design isn’t getting a functional design, it’s getting a design that’s both functional and manufacturable.

So many other fields are harnessing AI to design manufacturable hardware, so why is the electronics industry seeming to lag behind? At Flux, we’re changing that by building AI right into the PCB design tool. That way, hardware teams can design PCBs that are ready for manufacturing on the first try.

Designing a PCB that is ready for manufacturing involves navigating a complex landscape of technical and logistical challenges.

As a designer, your primary obstacles include ensuring signal integrity, managing thermal loads, adhering to manufacturing tolerances, and selecting appropriate materials, to name a few. If there’s an oversight on even one of these considerations, your whole system is likely to fail in the field. Keeping track of so many considerations is extremely difficult, if not impossible.

AI design assistants offer a solution by providing hardware teams with tailor-made, highly detailed design reviews. Just like having another senior EE on your team, AI design assistants like Flux Copilot are trained to know the industry’s best practices and manufacturing pitfalls. First, provide your AI with a template of precise design rules, manufacturing tolerances, and constraints. Then watch it analyze your design to enforce adherence to manufacturing tolerances, automatically detecting and flagging any violations in the design.

Now you can catch issues earlier on, so your team spends less time on manual checks and revisions, accelerating the design-to-manufacturing transition.

Studies indicate that 75–80 percent of PCB layout errors occur due to incorrectly created parts. Most of these mistakes result from the error-prone and tedious process of manually creating parts from datasheets. But with AI in your workflow, these kinds of errors are a thing of the past.

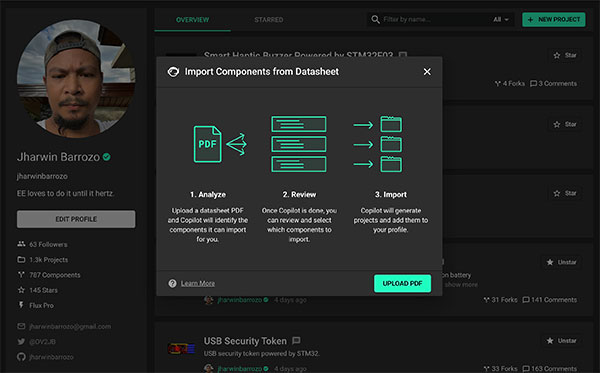

AI design assistants like Flux Copilot have the power to take the datasheet of a part as input and produce a completely accurate, ready-to-use part as an output. Now, instead of manual part creation, your process can look like:

This new, AI-powered workflow takes what used to account for up to 80% of design errors and reduces it to a quick and reliable automated process. The time and effort saved by using AI for part creation means your team can be more productive and get real, manufacturable products to market faster.

Traditionally, reviewing your bill-of-materials (BOM) has been a manual, time-intensive process prone to human error, leading to potential delays, increased costs, and issues in part manufacturability. However, integrating AI into BOM review processes can greatly enhance accuracy, efficiency, and overall production readiness.

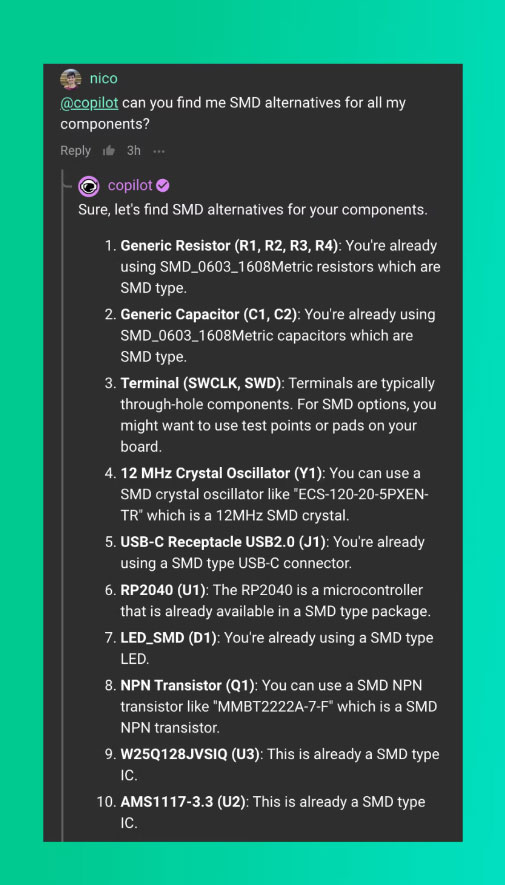

In a post-COVID world, ensuring that the parts on your BOM can actually be sourced for manufacturing is a huge concern. AI BOM review can automate the validation of part numbers and specifications against manufacturer databases, ensuring that the components listed in the BOM are correct and currently available, reducing the risk of production delays due to obsolete or out-of-stock parts. Furthermore, tools like Flux Copilot can identify alternate components that meet the design criteria, offering flexibility in sourcing and potential cost reductions without compromising the design integrity.

AI can also assess the incompatibility of components within your BOM, ensuring that all parts are mutually compatible and meet the design’s electrical, mechanical, and thermal requirements. This minimizes the risk of rework and redesign, which are often necessary when incompatibilities are discovered later in the manufacturing process.

Designing manufacturable hardware has historically been difficult, but it doesn’t have to be that way. At Flux, we’re bringing the power of AI to the design tool so that hardware teams across the world can innovate and bring new products to market faster than ever before. So far, we’ve helped over 175,000 engineers design their PCBs. Are you next?

Matthias Wagner is the founder and CEO of the hardware design platform Flux. He has worked in product and tech roles since 2004, and has previously served as a product manager for Meta and as a product management instructor for General Assembly. Wagner holds a degree in system and telecommunication engineering from Siemens AG.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.