Combining advanced lubrication methods is driving cleaner, more efficient, and cost-saving manufacturing solutions for U.S. industries.

By Maria Iruj

When manufacturing comes to mind, many visualize automation, robotics, or supply chains. Rarely does anyone focus on lubrication, yet the oils and fluids enabling machinery are critical drivers of energy use, environmental impact, and operational costs. Each year, factories worldwide, and especially those in the U.S., consume millions of gallons of lubricants. These fluids are not just expensive to purchase; they also carry high disposal costs and health risks for workers and the environment. The U.S. Environmental Protection Agency ranks waste fluid management as a leading hidden expense in machining operations.

One of my research published in 2024 by (Elsevier), point to “hybrid lubrication systems” as a practical, sustainable alternative. These systems combine multiple lubrication methods like minimum quantity lubrication (MQL), nanofluid-assisted cooling, and solid lubricants to deliver better performance with notably less environmental impact.

Manufacturing is responsible for about one-third of America’s total energy consumption, according to the Department of Energy. Even incremental improvements in efficiency can deliver billions in savings and substantial emission cuts. In machining, energy is often lost to friction and heat; while traditional lubrication fights these challenges, it does so with significant ecological downsides.

Hybrid lubrication upends this dilemma. By reducing tool wear, improving surface quality, and extending machine life, hybrid systems simultaneously slash reliance on wasteful coolants. Early industrial studies report up to 70% reductions in fluid consumption, with parallel gains in machining precision and productivity.

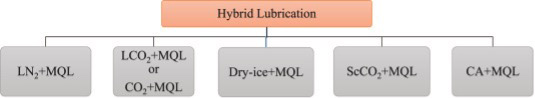

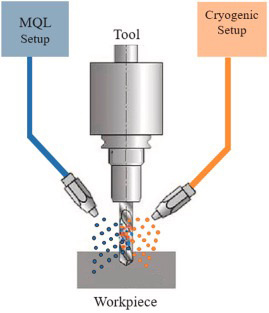

Unlike single-method lubrication, hybrid systems integrate several advanced technologies. Examples include:

The result is a synergistic effect, which supports for lower energy demand, cooler machine operations, and less fluid disposal—all benefiting both equipment performance and the environment.

This technology is transformative for sectors where precision machining is non-negotiable—such as aerospace, automotive, defence, and advanced manufacturing. With the U.S. setting ambitious climate and efficiency targets, an industry-wide shift to hybrid lubrication would deliver cost cuts, fortify American manufacturing leadership, and support long-term sustainability commitments.

Imagine aerospace leaders like Boeing extending tool life on jet engine parts, or Detroit’s automotive hubs slashing coolant waste without sacrificing output. The economic and ecological ripple effects would be felt nationwide.

Cutting fluids are notoriously difficult to recycle, and improper disposal contaminates soil and waterways, creating regulatory and health challenges. By dramatically lowering fluid volumes, hybrid lubrication yields lighter environmental footprints, more straightforward compliance, and a safer workplace. Fewer hazardous fluids also mean less exposure risk for machinists.

For hybrid lubrication to become a U.S. manufacturing standard, three enablers are essential:

From the assembly line innovations of Henry Ford to today’s smart factories, the U.S. has led in manufacturing ingenuity. Hybrid lubrication is the next leap, aligning with sustainability objectives and competitive advantage. Delivering on climate goals while bolstering industry means embracing this technological shift.

To all stakeholders—manufacturers, policymakers, researchers—the opportunity is clear: hybrid lubrication is more than a technical upgrade; it’s a practical path to cleaner, smarter, and more sustainable production.

Sometimes, pioneering progress means rethinking basics, like how machinery stays running. Hybrid lubrication is poised to help American factories cut costs, save energy, and protect the planet—all by changing what’s inside the machine.

About the Author:

Maria Iruj is an expert in sustainable manufacturing technologies.

An academic professional and interdisciplinary researcher with over 11 years of experience in engineering education, safety practices, sustainable innovation, and climate-adaptive technologies. Her work is grounded in mechanical and manufacturing engineering, but reaches beyond to integrate AI, environmental policy, and global sustainable development goals. With a strong background in mechanical engineering, she works at the intersection of education, sustainability, and innovation. Currently pursuing PhD in Advanced Manufacturing Engineering and leading research on AI-driven environmental solutions.

For inquiries, collaboration, or speaking engagements, visit www.linkedin.com/in/maria-iruj-58190164.

Read more from the author:

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.