A buyer’s playbook to stabilize gear lead time without gambling on quality – align specs, process controls, and acceptance checks early.

When a gearbox program slips, the first question is simple: “Where is the gear set?” The second is harder: “Why did lead time change again?” In precision gear projects, surprises rarely come from one dramatic failure. They come from small misalignments that compound across a long chain—spec gaps, late drawing changes, heat-treat queues, rework loops, and inspection disputes at the finish line.

I’m Feng Liu, CEO of PairGears. We manufacture precision gears and gear shafts for agricultural machinery, heavy-duty trucks, construction equipment, and electrified drivetrains. Most “urgent” orders aren’t urgent on the shop floor—they’re uncertain at the buyer-supplier interface. This article is a practical playbook to stabilize gear lead time without gambling on quality.

A gear lead time is not one number. It’s the sum of many small lead times, plus variability between steps. The critical path can also shift depending on gear type, batch size, and documentation requirements.

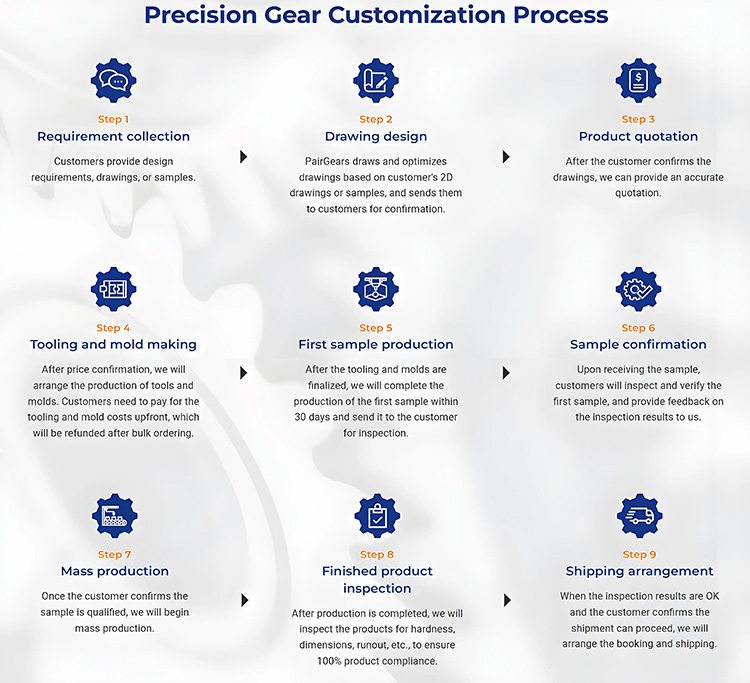

For a typical custom gear or gear set, the flow often looks like:

In most gear factories, two steps most often control delivery: heat treatment and final inspection. Industry Today has highlighted how real-time visibility and Industry 4.0 practices help manufacturers navigate supply chain disruptions—an idea that also applies to complex, multi-step gear supply chains.

Heat treatment is batch-based and capacity-constrained. If your part needs carburizing and quenching, furnace scheduling, loading/fixturing, and post-heat-treat allowance strategy all matter. A rushed plan may still meet hardness targets but create distortion that returns as grinding rework or scrap.

Final inspection is where assumptions become requirements. If buyer and supplier don’t align early on acceptance criteria (what’s critical, how to measure it, what records must ship), parts can be finished yet commercially “not deliverable.” Advanced analytics can improve visibility and agility—often reducing lead-time risk in complex supply chains.

When delivery pressure rises, teams often compress steps that feel “administrative”: clarification, validation, and inspection planning. That’s exactly where risk increases. The fastest gear project is the one with the fewest rework loops—not the one with the fewest stated steps.

Three shortcuts often backfire:

1) Skipping the DFM conversation. A drawing can be manufacturable in theory but unstable in production. Datum choices, surface requirements, and tolerance stacks may force extra setups or high scrap risk—turning a promised date into a moving target.

2) Treating heat treatment like a black box. Without a clear allowance plan and distortion-control approach, you can hit hardness but miss geometry, triggering rework and extra inspection. Those loops are usually longer than the time saved by rushing earlier steps.

3) Leaving inspection as pass/fail at the end. If the inspection plan isn’t matched to risk, you either over-inspect everything (slow) or under-check true critical-to-quality features (quality escapes). Either way, delivery becomes fragile.

To stabilize gear lead time, you need a shared map of what is being decided, and when. This lightweight map works for new designs and repeat orders.

Align quickly on:

This is not about writing a novel—it’s about preventing hidden requirements from appearing after manufacturing starts.

Tolerances should protect function, not just look impressive on paper. For a deeper look at how gear tolerances drive cost, measurement choices, and rework risk, see my earlier article on gear tolerances.

At minimum, align on:

For case-hardened gears, plan heat treat as a milestone:

If an inspection requirement is important enough to reject parts, it’s important enough to plan before the last operation. Define:

Once the map is clear, improvements become targeted instead of emotional.

1) Reduce change frequency, not just cycle time. Late drawing changes are the most expensive form of speed. If the spec is still moving, shorten lead time by freezing decisions earlier—not by rushing production.

2) Design for stable datums and fewer setups. Every extra setup adds queue time and variation risk. Small changes like clearer datum definition, realistic surface finishes, or tolerances that reflect functional need can reduce both setups and inspection complexity.

3) Secure the heat-treat window early. If heat treat is the bottleneck, book it early and lock the route (process plus loading plus allowance strategy). Resiliency planning matters even more when global trade uncertainty increases schedule volatility across suppliers.

4) Focus inspection on the true CTQ features. Not every dimension deserves the same attention. Identify the features that control function and noise/life risk, then build a plan that checks those features reliably and efficiently.

If you’re a buyer or program owner, paste this into your RFQ email:

Gear lead time and gear quality are not enemies. They are outcomes of the same system: clarity up front, controlled process steps, and aligned acceptance criteria. If you want fewer surprises, don’t ask your supplier to move faster in a vague way. Ask for a lead-time map, identify real bottlenecks, and remove rework loops before they start.

At PairGears, we’ve found that predictable delivery is built in the first week of communication, not in the last week of expediting. If your next gear project is time-sensitive, start with alignment—and the calendar will follow.

Send your RFQ. We’ll reply with a realistic lead-time map and a quality-control plan.

About the Author:

Feng Liu is the CEO of PairGears, a precision gear and shaft manufacturer serving agricultural machinery, heavy-duty trucks, construction equipment, and electrified drivetrains. He focuses on manufacturability, gear quality control, and buyer-supplier alignment that improves on-time delivery in custom gear manufacturing.

Read more from the author:

What I Wish More Clients Knew About Gear Tolerances | LinkedIn, August 8, 2025

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.