Yard Management software can identify safety risks and blind spots with the help of Artificial Intelligence.

By: Doug Lawson, CEO of ThinkIQ

The European Union, China, and the United States are the top three largest global manufacturers, respectively. The U.S. manufacturing industry consists of hundreds of thousands of companies and significantly contributes to the global economy, representing about 11% of America’s overall gross domestic product.

This industry heavily depends on efficiency in the manufacturing yards, but these sites present unique obstacles to safety. Businesses want to safeguard their manufacturing processes, materials, and assets while ensuring employee safety and constructing an efficient operation.

Due to the sheer size of certain production yards, managers may find it challenging to maintain visibility in all areas. However, visibility issues can be resolved by yard management software that utilizes artificial intelligence (AI) technology. AI surpasses conventional security measures by analyzing previous data and information to notify managers of potential safety risks and security blind spots.

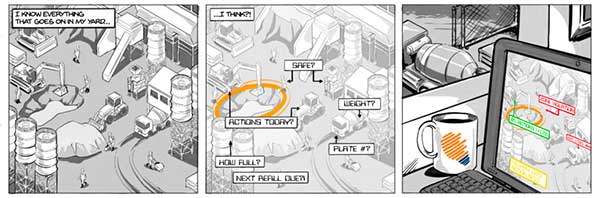

AI-powered yard management systems offer functionality and flexible strategies to fit specific company objectives. Frequently, they include visualization of a facility through a live graphic to see activity in real-time in addition to scheduling and appointment capabilities to direct the flow of traffic. As a result, organizations can identify significant areas for improvement in their manufacturing systems with the right AI-powered solution.

Manufacturing yards must function on a routine schedule, similar to other industrial production zones. The manufacturing production cycle consists of everyday processes and tasks that depend on a specific schedule. Although there is some flexibility, most yard operations function in a timely manner.

With the help of machines equipped with camera sensors, these yards can contain a large amount of data and analytics. When analyzed correctly, this data offers business-wide awareness of key performance indicators and other crucial insights. By leveraging the cloud, manufacturers can interface with other warehouse management systems and receive actionable data wherever they are. In addition, these platforms can seamlessly interconnect to support AI operations without the need for internal IT resources or complex system integrations.

Video footage captured in the manufacturing yard can now be analyzed by AI. Businesses can train the software to scan for employee errors, determine best practices to boost productivity, and warn employees of possible dangers before they occur.

For example, employees who work alone and do not wear the proper protective equipment or work close to an area of heavy traffic put themselves and others’ safety in danger. By leveraging AI and continuous monitoring systems, managers can receive warnings of potential incidents before they occur, effectively exposing blind spots.

In addition, AI-powered management systems can identify vehicles entering the yard through license plates or container identifiers, which can then notify managers when a vehicle enters and exits the yard. With this new information, managers can ensure the correct vehicles are being transported and sticking to their appropriate schedule.

These previously hidden blind spots become visible when AI is implemented in the manufacturing yard. It is a top priority for manufacturers to identify the variety of blind spots in their yard since they frequently raise risk and expense concerns. It will benefit a company both now and in the future to identify these yard hazards and modify procedures in response to this information.

AI can be used in manufacturing yards to enhance safety and find operational efficiencies, such as load-out cycle durations, production obstacles, large production waste levels, or low worker output.

Unfortunately, many manufacturing firms are hesitant to adopt this technology because they are comfortable with their current operations. With AI-powered systems, organizations can collect and analyze their yard data to identify opportunities for growth.

However, implementing these smart technologies is not always simple. Instead of relying on systems integrators’ recommendations, organizations must choose the most suitable option that supports their objectives as a company. Careful planning and execution is required for these AI systems to properly work.

Companies must approach deployment and compatibility with current systems strategically. Maximizing business output must be a continuous effort, not a quick remedy. Manufacturing firms must create an effective communication model to educate and inform staff members about changes. For AI to fully deliver on its promise, employers must apply the knowledge gained from AI systems and upskill their workforce accordingly.

Manufacturing yards consist of various challenges that call for innovative solutions to enhance supplier cooperation, predictive maintenance, and overall yield. It’s crucial for manufacturing leaders to recognize how emerging technologies will aid their growth as they strive for continuous improvement. Successful managers should attempt to understand their yard’s operations better, identifying its shortcomings and offering solutions to improve.

Although each manufacturing process is unique, there are also certain similarities. Applying solutions that offer a personalized approach can significantly improve outcomes. After all, manufacturers should leverage every advantage possible in today’s fiercely competitive market.

About the Author:

Doug has founded, built and sold multiple software startups in the Industrial Sector. His understanding of customer challenges and his leadership creating innovative products to meet those challenges is widely respected in the industry. The products from his startups are used in nearly a million plants globally. On a personal level ThinkIQ is the logical culmination of his career and, as CEO, he is intentionally creating a company that will have global impact, delivering enormous value to its customers, creating safer, better and trustable products with less environmental impact.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.