How to choose the right industrial ventilation equipment for your lab.

Ventilation is one of the most critical components of any laboratory, as they help minimize the risk of contamination of the surroundings. In fact, one of the biggest safety hazards you have to worry about in a lab is the air itself. Chemicals, toxic fumes, and vapors can all contaminate the air and make it harmful to breathe. This is why proper ventilation is critical in any lab. Proper ventilation allows for the rapid removal of unwanted impurities from the air.

When building a lab, your choice of ventilation equipment can have a huge impact on the safety of the building and the surrounding environment. Thus, it’s necessary to get the ventilation system right the first time. But how do you know which industrial ventilation equipment is the right one to use? Here are basic things to consider.

1. Proper And Adequate Air Circulation

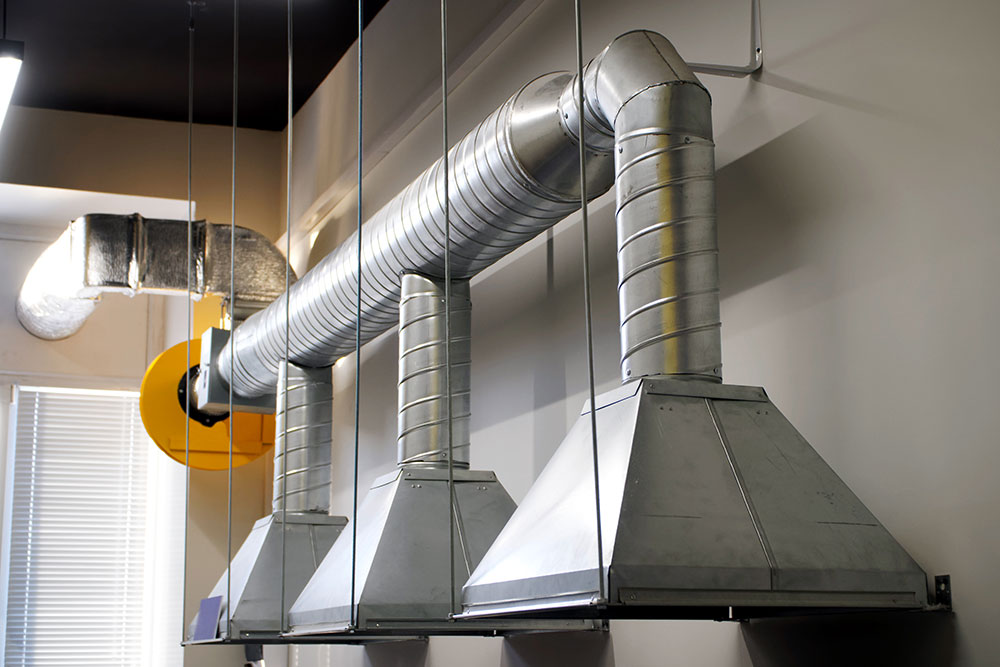

Lab ventilation equipment includes air ducts, air conditioners, ventilators, exhaust fans, air cleaners, carbon dioxide scrubbers, dehumidifiers, ozone generators, heaters, ozone generators, heat exchangers, refrigeration devices, air compressors, wastewater treatment equipment, humidifiers, and air purifiers.

The right ventilation equipment for any lab must have proper and adequate air circulation. You can’t compromise this if you want to minimize contamination. Depending on how big the lab is, you’ll need to get ventilation equipment that can cater to the size of the lab without any hassles. Without an adequate ventilation system, you can’t control the airflow, and this can jeopardize the required health levels and safety guidelines.

In a very controlled environment like a lab, the need for the right ventilation system becomes more crucial. Perhaps this is why the makeup air unit is one of the fastest recommended ventilation equipment for labs. They’re ideal for spaces where the environment requires a higher need for ventilation to improve air quality and protect the health of the occupants. Experts such as R. Williamson & Associates. And other industry professionals could provide more information on these units if you ask for consultations.

Proper ventilation in a lab also means no operable windows. This is because windows that can be opened might disrupt negative pressure containment and jeopardize fume hood containment.

2. Location

Another factor to consider when selecting ventilation equipment for a lab is the location. The area where the lab is situated could significantly affect the equipment’s safety and efficiency. For example, if the lab is located in a crowded place, many people walking by every day can create air turbulence that forces contaminants to escape into the lab atmosphere. A lab that uses an air diffuser above the fume hood may also trigger air turbulence that allows contaminants to enter into the lab.

Besides, labs located in urban areas and cities can suffer from poor outdoor air quality and excessive noise, making natural ventilation impossible. Likewise, rural locations may suffer from high pollen concentration, necessitating the need for a filtration ventilation system. Therefore, to get the right ventilation equipment for your lab, you’ll need to consider what suits your environment and the climatic conditions that may affect your choice. One needs to be sure about such aspects to secure the safety in the lab.

3. Type Of Lab

The kind of lab you’re going for can also influence your choice of the right ventilation system. For instance, a medical lab would require ventilation equipment that can protect employees and patients from excessive humidity and other elements that can cause serious health complications.

A chemical lab, on the other hand, would require a filtration system that maintains the air pressure in the lab without disrupting the delicate elements. If you’re unsure about the type of ventilation equipment your lab needs, you can get a professional to inspect your facility to ensure that you have the right equipment.

4. Noise Management

Noise management capacity is another important consideration when installing ventilation systems for a laboratory. You may need to conduct noise studies around the lab area to determine the noise levels of the area and the old ventilation system if there’s one. Doing this will help you know the best ventilation system that’d be ideal for noise management in the lab.

Modern ventilation systems are designed for noise management; they have a quieter motor that delivers lower vibration and noise levels. In tightly controlled labs where noise has to be eliminated or reduced to the most minimum level, it’s better to go for ventilation systems integrated with noise attenuators to control the noise.

In case you’re using axial exhaust systems, they could also be designed with noise reduction tools to minimize the noise.

5. Energy Efficiency

Some ventilation systems are more efficient than others. You’ll need to consider energy efficiency if you intend to reduce energy costs in your lab. For instance, direct-drive fans with mixed flow impeller are a more energy-efficient choice for fume hoods than centrifugal fans.

More so, using ventilation systems with variable speed drives can also help reduce energy consumption and costs. It lowers fan speeds at night when the lab is empty and optimizes usage for when it’s occupied. It’s also possible to save energy by recovering the heat lost through exhaust air. You can equip your ventilation system with heat recovery components to extract some of the air in the exhaust and transfer it to complement the lab’s heating ventilation system, thereby reducing heating costs.

Getting the right ventilation equipment for your lab depends on several factors, ranging from location, the need for noise management, and energy efficiency, for starters. Make sure you take the time to research before making a choice. Doing this will help you find the right ventilation equipment so that you don’t spend any additional money to replace it in case it turns out to be of low quality.

Nicholas Cox

Nicholas Cox is a successful blogger who have been writing topics about business and home improvement for years. Nicholas gained thousands of loyal readers through the years because of his ability to write informative and witty articles.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.