Volume 27 | Issue 3

Click here to read the complete illustrated article or continue below to read the text article.

The U.S. manufacturing sector stands at a pivotal crossroad. As the sector emerges from the disruptions of recent years, we face a pressing workforce challenge.

Recent research found that industry leaders are seeing large gaps between the job skills required and candidates’ skill set. The Future of Manufacturing research report by The American Society of Mechanical Engineers (ASME) and Autodesk, Inc. revealed that the skills gap will only widen as manufacturing firms accelerate their digital transformation to Industry 4.0.

Furthermore, it’s not just that existing necessary skills are lacking, it’s that the new skills needed aren’t being developed. “Emerging technologies including design for manufacturing, operations technology infrastructure, and artificial intelligence/machine learning technologies will require new skills of mechanical and manufacturing engineers and machinists,” according to the report.

The researchers recommend training and education to develop these “hard skills” for current and future employees. In addition, engineers and machinists will need strong “soft skills” including creative problem solving, communication, and collaboration, and interdisciplinary skills to close gaps for each job role.

As industries grapple with talent shortages and employee retention challenges, company investment in K-12 STEM programs has emerged as a strategic solution. While the short-term outlook demands quick, innovative solutions to address immediate labor shortages, the long-term picture requires an approach to ensure sustainable growth and competitiveness.

By championing science, technology, engineering, and mathematics education from an early age, companies are not only fostering a new generation of skilled workers but also enhancing current employee satisfaction and loyalty by supporting their mentoring activity and community involvement. This dual impact underscores the critical role of corporate engagement in shaping the future of STEM fields while addressing immediate workforce needs.

Professional organizations such as ASME offer programs for members and employers that make investments in K-12 STEM education easier to implement. The Society’s multiple program pathways in K-12 STEM education champion the power of being a problem-solver for good to more than 70,000 students annually.

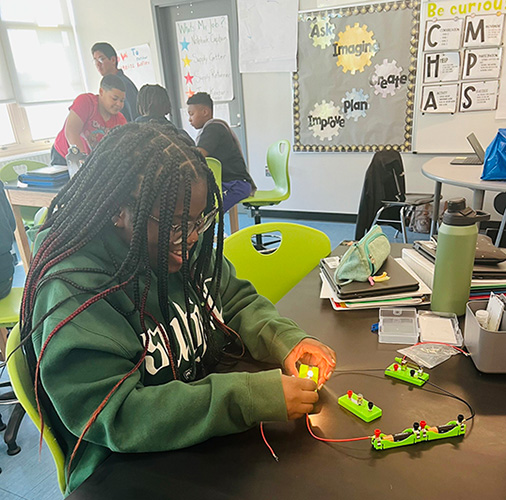

Typically, engineering is taught within science technology and math without distinction when discussing STEM. ASME brings the E, the Engineering, in STEM forward, emphasizing the creative, critical skill sets vital to group problem-solving within the classroom experience.

Alongside global education technology leader Discovery Education, ASME helps inspire students through Career Connect, a platform connecting employees with teachers and K-12 students in the classroom, as well as an educational program called Engineering Dreams offering K-12 students free STEM resources. The cornerstone of all ASME K-12 engineering education program elements is a commitment to showcasing real-world stories and related in-class experiences to infuse the optimism, empathy, and creativity that is vital to truly opening the door to “thinking like an engineer.”

“Our programs rely on the support of industry partners, including the participation of their employees in these dynamic classroom experiences,” says Stephanie Viola, executive director of the ASME Foundation and managing director of ASME Philanthropy. “Industry engagement is the linchpin to ensuring the authenticity and relevance of STEM initiatives. These programs bring engineering to life, demonstrating its unlimited possibilities to young students.”

Whether they are delivered digitally, virtually or in person, ASME STEM-readiness programs amplify the Engineering in STEM and the power of a problem-solving mindset through critical skill development, mentoring, and modeling. They focus on real-world applications of engineering solutions, the power of diverse teams, related hands-on activities, and feature STEM professionals who share their unique professional journey.

“In the short term, employers can increase employee satisfaction and retention by supporting their employees’ involvement in the classroom,” says Viola. “It’s highly validating, both personally and professionally, to share the impact of your work on a community and spark interest in engineering and STEM at large in young people. In the long term, the investment of employees’ time in the classroom helps build a pipeline of future talent for industry.”

ASME K-12 engineering education programs include:

By championing STEM education from an early age, companies can not only foster a new generation of skilled workers but also enhance current employee satisfaction and loyalty by supporting employee-mentors in the classroom. ASME, Discovery Education, and other program leaders make it easy for companies to increase their community engagement with extensive networks and processes already tested in K-12 schools across the country. It’s a win-win and highlights the critical role of corporate engagement in shaping the future of STEM fields while addressing immediate workforce needs.

About the Author:

Patti Jo Rosenthal, K-12 STEM Manager, The American Society of Mechanical Engineers (ASME), develops the Society’s nationally scaled STEM education initiatives, producing content and related, hands-on experiences designed to bring real-world relevance and context into the classroom. Sparking their curiosity, students are introduced to the critical skill sets needed to “think like an engineer.” ASME’s multiple program pathways in K-12 STEM education champion the power of being a problem-solver for good to more than 70,000 students annually, 71% of whom are from Title 1 school communities.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.