By Dr. Sanjoy Paul, Vice President, Manufacturing & Technology, Wipro Limited

Survival in the new age of digital transformations means every business has to embrace digital or run the risk of becoming irrelevant in the near future. In fact, the average lifetime of S&P 500 companies has shrunk to about 10 years over the last three decades and, within the next 10 years, 40 percent of S&P 500 companies will cease to exist unless they keep up with the digital technology trends. Digital transformation is therefore not an option but a necessity.

Digital is about outcome: efficiency, experience, insights or new business models. However, these outcomes result from the innovative usage and combination of new-age technologies, such as IoT, Mobility, Social, Cloud, Analytics and AI. According to industry estimates by McKinsey & Company, IoT could create an opportunity of up to $11.1 trillion across industries by 2025, out of which the manufacturing industries would benefit the most ($3.7 trillion). Most of the benefit will come from higher asset utilization, higher employee productivity, better customer experience, innovation, and elimination of waste in supply chain and logistics.

In order to leverage the power of these technologies, every company would need to use a platform that incorporates these technologies and enables building of applications on top. Given the time and resources needed to build such a platform, it does not make economic sense for every company to build it on its own. A far better idea is to build a common platform that caters to an industry – an industry platform – that all stakeholders associated with the industry can use. An Industry Platform serves multiple purposes:

Cost sharing makes sense as not every stakeholder would have to invest unilaterally to both build and also maintain and upgrade such a platform with new technologies on a continuous basis. Keeping the platform current is a complex task and it requires specialized skills to make that happen. For many companies, building platform is not their core strength. Platform is just an enabler and, hence, being able to leverage a common platform built by the experts would be their best bet.

As stakeholders of an industry use a common platform, each stakeholder will experience the network effect. Metcalfe’s law states that the value of a network is proportional to the square of the number of connected users of the system (n2). When the network grows very large, it leads to the formation of sub-groups and even higher benefits as stated by David P. Reed. Reed’s Law states that the “utility” of large networks can scale exponentially with the size of the network. Thus, as new members join the platform, the benefits to the stakeholders increase exponentially.

As every member in the platform can potentially connect to every other member and share its information, there could be bi-lateral or multi-lateral business models based on what information the concerned parties share and for what purpose. In the terminology of David P. Reed, there would be Group-Forming Networks and every such network can potentially have its own business model.

IDC predicts that by 2018, more than 50 percent of large enterprises – and more than 80 percent of enterprises with advanced digital transformation strategies – will create and/or collaborate with industry platforms. While traditional value-chain business models lead to linear value creation, the platform-driven business models lead to two-way value creation in a continuous manner.

There are several challenges associated with sharing a common platform among the vendors, suppliers, distributors, partners, alliances and even competitors. Here are some of the issues that need to be handled carefully:

Access control would ensure that only the legitimate members have access to the platform and to the data stored in the platform. A federated access control mechanism is desirable for flexibility.

Data governance would allow the right parties to access the right data at the right time. This requires very fine-grained modeling of data – both from asset hierarchy point of view as well as from ownership/organization angle. Once the data elements and the relationship amongst them is modeled in a fine-grained manner, authorization to access the data elements can be enforced in an effective manner.

Dynamic partnership would ensure that two or more parties share desired data amongst themselves only for the duration of time they collaborate with one another. This requires usage of time-based contracts and enforcement by making changes in the authorization process during and after the period of collaboration.

Let me explain the above concepts via a simple eco-system in the context of the marine industry. There are multiple stakeholders in the marine industry: (1) Ship Owners, (2) Ship Operators, (3) OEMs, (4) Service Providers, etc.

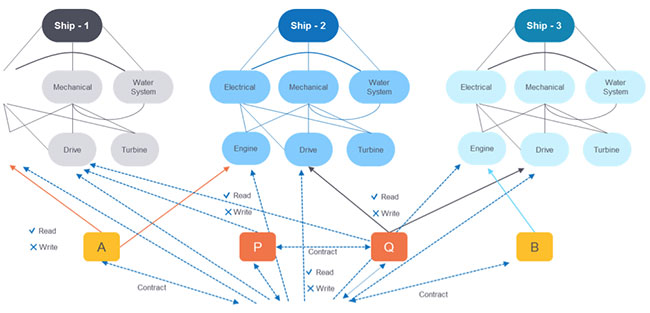

A ship is a complex asset with multiple components: (1) Electrical, (2) Mechanical, (3) Water system etc. Both electrical and mechanical components exist in Engine, Drive and Turbine. Thus, a ship can be modeled as a graph as shown below. Furthermore, there is an ownership angle to the assets and their components. There may be multiple OEMs providing engines and drives. In the diagram below, there are OEMs A and B providing the engines and OEMS P and Q providing the drives. This represents fine-grained data modeling.

Regarding data governance, OEM A is authorized to access engine data from ships 1 and 2 while OEM B is authorized to access engine data from ship 3. Similarly, OEM Q is authorized to access drive data from ships 2 and 3 while OEM P is authorized to access drive data from ship 1. Moreover, these OEMs, by virtue of being the owner of the respective assets, have both Read and Write access to the data.

Dynamic collaboration can be achieved between OEMs P and Q enabling OEM Q to access the drive data in ship 1 for an agreed upon duration of time via a contract. Note that Q may have just the Read access but not the Write access to the drive data in ship 1.

Similarly, the Ship Operator may have Read access to the engine and drive data in all three ships via a contract with the corresponding OEMs. This has the potential of new revenue generation for the OEMs by selling their data feed to the ship operator who needs the data for optimizing its operational expenses.

The above example illustrates how an industry platform, via fine-grained data governance and dynamic partnership between multiple parties, can enable new business models or new revenue streams that did not exist before.

While the above example illustrated the value of an industry platform in the context of the marine industry, similar concept involving multiple stakeholders exist in every industry, necessitating industry platforms in respective domains. In addition, it is becoming increasingly clear that having a platform strategy and the business know-how to exploit it is more important than ‘owning’ a suite of products no matter how extensive the product portfolio is, as it is not possible to match the exponential benefit provided by a platform via the network effect of the ecosystem partners.

Author Bio

Author Bio

Dr. Sanjoy Paul is responsible for driving profitable growth of clients via innovative digital technologies and business process transformations. Sanjoy has over 25 years of experience, the last 10 years being in the IT industry and the previous 15 in the technology, internet and telecommunications domains.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.