July 25, 2019

We are in the midst of a manufacturing revolution — Industry 4.0. My last post discussed the critical transformation manufacturers are making in this new era — from a focus on products to services. With IoT projected to explode, adding $14.2 trillion to the global economy by 2030, manufacturers face a huge opportunity.

Industry leaders like Caterpillar and Siemens are already leading the charge in Industry 4.0 with the production of connected machines and the launch of technology-driven, subscription-based solutions. However, many are still in the infancy of their transformations.

As more manufacturers follow suit to remain competitive, modeling their businesses into platforms for services and adopting subscription business models, it’s important to set expectations: no, this isn’t an overnight transformation, and yes, there are challenges ahead.

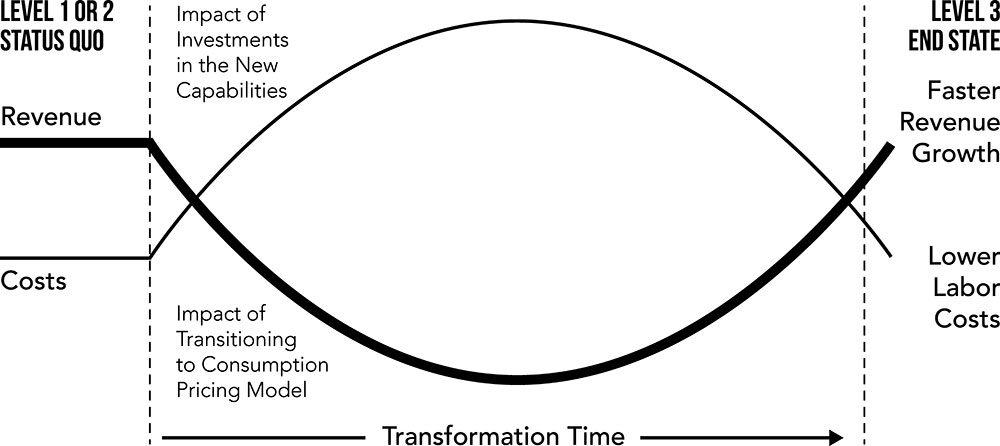

One such challenge is the initial revenue impact, referred to as the “swallowing the fish” effect. In the early stages of a business transformation as a company begins to shift its revenue mix, we often see the revenue curve temporarily dip below the operating expense curve before climbing back upward again. Marked by higher costs and lower revenue, it’s a short-term reality as organizations shift focus from maximizing products sold, to fostering long-term relationships with customers, and can vary based on industry.

Swallowing the Fish

While we’ve seen transformations in the SaaS industry take 2-5 years on average, the manufacturing industry will likely take longer due to the tangible aspect of products and associated marginal cost of core solutions being sold (think construction machinery versus productivity software).

However, this shouldn’t deter leaders from making the leap to subscription models. Costs eventually go down and revenue comes back up in the form of predictable recurring revenue.

Key to a successful transformation is the consistent measurement of monetization metrics in real time. While backward-looking, conventional GAAP metrics like cost of goods sold and gross profit still serve a purpose, to prove the value of the subscription model and optimize customer relationships, manufacturers must consider and track a new set of forward-looking metrics.

1. Annual Recurring Revenue (ARR)

ARR is the amount of revenue a company expects to repeat in a year, which provides a holistic view of a company’s health. With ARR as the foundational metric, companies can forecast revenue, set realistic goals, and make informed decisions to maximize growth.

2. Churn Rate (Attrition Rate)

Churn rate is the rate at which a business loses subscribers, and something that becomes critical as you grow your subscriber base. It is 5x more expensive to acquire a new customer than to maintain an existing one. Cyril Perducat, EVP Digital Services & IoT at Schneider Electric, explains, “customer retention, at a very eye-level, is paramount. If you spend money to acquire customers but you lose them as fast as you acquire them because you don’t provide the right experience, then its an economic business model that will not scale at all.”

3. Customer Lifetime Value (CLV)

CLV may be a novel concept for manufacturers. It’s the expected amount of money a customer will spend throughout the customer lifecycle, taking into account the cost to acquire new customers and maintain existing ones. It should be the ultimate indicator of which customer acquisition channels are most profitable and can serve as a guide for pricing and packaging strategies.

4. Average Revenue Per User (ARPU)

ARPU is calculated by dividing revenue from all services provided by number of consumers. Having a per-user view of revenue is useful to measure how successful pricing and packaging strategies are, whether the sales and marketing team’s value propositions are consistently improving, and if the value of a product is being aligned with the right customer. It can be a valuable indicator of what CLV goals should be.

5. Growth Efficiency Index (GEI):

GEI boils down to how much it costs a company to acquire new customers — how much it costs to acquire $1 of ARR. Using it, manufacturers can spend at least enough to replace customers churned. What’s left can be booked as profits or re-invested in growth. With this insight, companies have more flexibility to be bullish or conservative. GEI will fluctuate with the initial transition to a subscription model, and also as a company matures and begins to offer new products and expand into new markets.

There are countless opportunities for manufacturers who shift their business focus to provide valuable ongoing services fueled by subscriptions. Research shows over the last 7 years, subscription businesses across all industries have grown revenues 5x faster than S&P 500 companies. The metrics discussed are key to driving this growth and establishing a solid market valuation. The question remains: how quickly can manufacturers embrace business model innovations, leveraging industry 4.0 enablers (IoT, Cloud, AI…) to create new revenue streams?

Michael Mansard is a seasoned Subscription Economy business strategist. He currently serves as Principal, Business Transformation & Innovation within Zuora’s Strategy & Operations field group.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.